Contributing to Further Energy Efficiency of Automobiles!

NTN Develops High-Accuracy Bearing Torque Calculation Method

- Unraveling the mechanism behind torque increase, and applying to the development of low-torque bearing technology in the future

NTN Corporation (hereafter, NTN) has developed a new torque calculation method for ball bearings operating under oil lubrication that improves calculation accuracy by up to 50% compared to conventional methods when operating at high rotational speeds. This technology will be applied to the development of further low-torque bearing technologies and contribute to improving the accuracy of preliminary calculations during customer design processes.

Bearing torque significantly affects the performance and energy efficiency of the applications in which bearings are used. When applying bearings to customer applications, torque calculations are typically performed using proprietary calculation programs developed by bearing manufacturers.

In recent years, as energy efficiency improvements in EVs (electric vehicles) and HEVs (hybrid vehicles) have progressed, developing low-torque bearings for the motors and gearboxes of these vehicles has become a universal challenge. These bearings require higher rotational speed performance than before, driving the need for advanced calculation methods capable of accurately predicting torque even under such conditions.

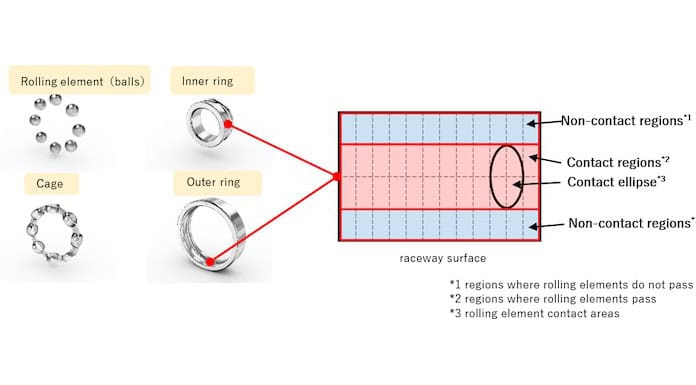

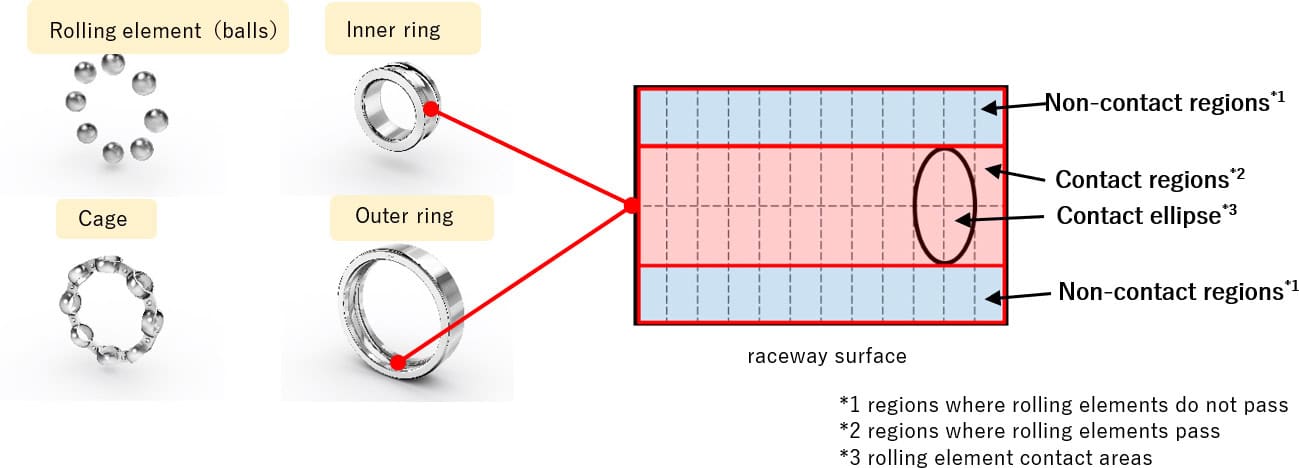

The newly developed torque calculation method focuses on the raceway surface through which the bearing balls pass, separating the contact and non-contact regions for calculation. Conventional methods considered only the contact region, but by also including the non-contact region, this new approach enables more accurate calculation of torque-generating factors and clarifies the mechanisms by which each factor contributes to torque increase. As a result, NTN has improved torque calculation accuracy at high rotational speeds by up to 50% compared to conventional methods. A formula that can be applied across a wide range of operating conditions has been developed and implemented in NTN’s proprietary calculation programs.

By clarifying the factors that influence torque increase, this method makes it possible to quickly validate the effectiveness of the approaches previously considered useful for reducing torque through internal bearing design, and to identify which internal design strategies are most effective for achieving low-torque under various operating conditions. In the future, this method will also be applied to the development of low-torque technologies for various bearing components, such as lubricants and cages.

In addition, improving torque calculation accuracy at high rotational speeds will reduce internal workload and accelerate evaluation and proposal processes for EV bearings, where demand is expected to grow further.

NTN remains committed to meeting the growing demand for lower torque and energy efficiency in EVs, HEVs, and other fields through ongoing research and technological development, while also working to enhance research and development capabilities and accelerate development speed by leveraging digital technologies, including Model-Based Development (MBD).

Comparison of Torque calculation accuracy

Flow from Customer requirements to proposal

Source: NTN