Getting the balance right between bearings and correct lubrication can be a challenge but is essential to maximising bearing health and longevity. Here Andrew Howard, Lubricants and Adhesives Product Manager at Acorn Industrial Services and Andy Fletcher, Bearing and Maintenance Product Manager discuss common lubrication and bearing mistakes they have seen over the decades that have impacted bearing health, and illustrate the point using an offshore engineering example.

For many years Andrew worked in the bearings and lubrication industries as a chartered mechanical engineer in the oil and gas sector and Andy in R&D and application engineer roles at a leading bearing manufacturer. In the past five years they have both moved across to the supply side, and in their jobs at Acorn have seen a lot of the day-to-day challenges and mistakes from engineers and maintenance teams that encourage premature bearing failure.

Lubrication mistakes

When it comes to lubrication, the most common reasons for bearing failure can be summed up in three words: ‘over’, ‘under’ or ‘wrong’. Here are Andrew Howards thoughts on the subject:

- Over-lubrication must be the number one reason for premature bearing failure that I see in my daily work. Too much grease or oil increases the friction and heat for the bearing, leading to seal damage and eventual bearing failure. It is usually easy to spot over-lubrication when it gets to this stage, as there will be grease leakage, an increased temperature during operation or additional noise.

- Conversely, under-lubrication is almost as bad for bearing longevity, as insufficient amounts of grease or oil leads to metal-to-metal contact that inevitably leads to wear and overheating. The tell-tale signs of under-lubrication are a high operating temperature, unusual vibration and premature wear.

- Third on the list is using the wrong lubrication for the application or mixing incompatible thickeners or base oils. With different grease or oil viscosities and base types there is no guarantee that they will be able to handle the speeds, loads or temperatures thrown at them during normal operating conditions. The signs of the wrong lubricant use will usually be accompanied by excessive wear, noise, machine or grease breakdown and/or clogged lubrication paths.

Avoiding lubrication mistakes

So, how is it possible to avoid these common mistakes and get bearing lubrication right? Firstly, it is important to pay attention to OEM’s specifications for grease type, quantity and lubrication intervals, that are usually based on bearing size, speed, operating temperature, load and environmental conditions. If the manual advice isn’t specific enough, then calculations for grease volume from leading bearing companies are readily available.

Correct lubrication reapplication is equally as important. Manufacturer charts – based on operational conditions, online calculators and lubrication schedule spreadsheets – are good. Also, using ultrasound or vibration analysis, infrared thermography, or checking grease colour changes are useful indicators of lubrication needs. Another thing to take into consideration is lubrication application method.

When wrong bearing choice and wrong lubrication collide

Andy Fletcher discusses what happens when the wrong bearing choice and lubrication collide:

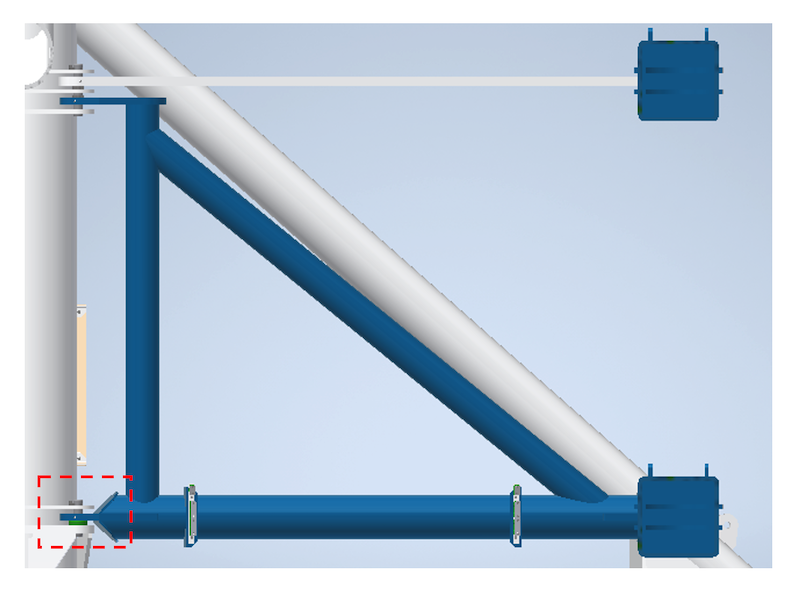

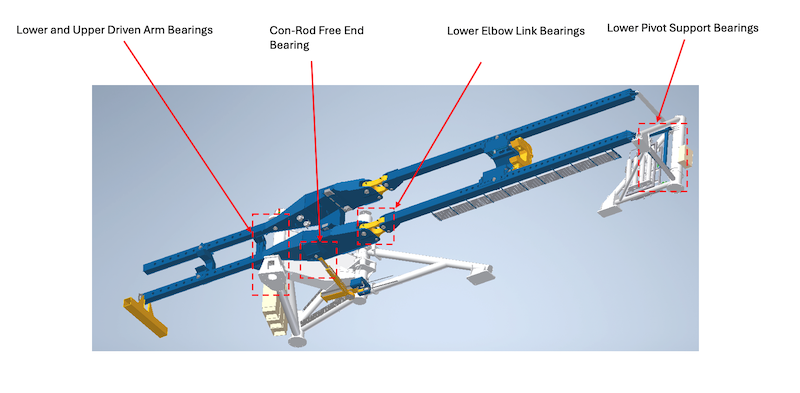

Acorn was called in to help an offshore product engineering company solve a problem they were having with blackening grease on some large oscillating bearings being used in a rig destined for offshore usage. Two lubrication issues were highlighted. Due to the position of the bearings, the lubrication was being added from above, when they weren’t in full oscillation, which led to dissipation issues. Also, the grease was getting hot and cooking.

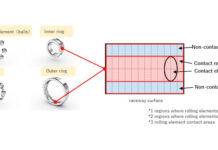

With regards to the bearings, the lower and upper pivot driven arms and elbow links featured spherical roller bearings that were showing signs of wear during the testing phase, prior to full-scale production of the rig. Unidirectional axial load was seen in most of the bearings and the rig’s use meant that these arms and elbow links would spend most of their lifetime at smaller oscillation amplitudes. On the removal and disassembly of the bearings to assess the problem further it became clear that false brinelling wear was being caused as a result of both radial and axial load and the bearings having only small angles of oscillation.

The design team had originally wanted to use spherical roller bearings on the rig to take advantage of their reduced resistance and subsequent ease of movement, compared to spherical plain bearings. Although improved efficiency was the end goal, the choice of bearing meant that the risk of premature failure was significantly increased in both the test and real-life scenarios.

Working with the design engineers, Acorn did a range of lifetime calculations on different bearing types – considering load and rotational constraints – to see if the same spherical roller bearing efficiency levels could be achieved by using smaller bearings, to minimise the effect of false brinelling as much as possible. It became clear that the spherical plain bearings originally recommended by Acorn were the only way to ensure bearing longevity and performance, as the test rigs were translated into their real-life equivalents offshore.

As a result, spherical plain bearings were installed to accommodate the smaller oscillation amplitudes, eradicate false brinelling and overcome the lubrication application problem. In addition, a grease was specified that had a higher operating temperature. Thanks to the use of the right lubrication and bearings, the result is a solution that has minimised the risk of unplanned bearing failure.

The wrong choice of lubrication and bearings in applications is more common than would be first thought. One of the underlying issues is that the full technical capabilities of the chosen grease are not assessed or understood. This is where a distributor such as Acorn, with expert advisors who have specialised in their sector for decades, comes into its own. By piecing together manufacturer information and marrying it up with the requirements of the specific application, Acorn can advise on the best-fit solutions and troubleshoot where necessary.

Unnecessary wear, downtime and cost can be avoided if the right lubricant and bearing are chosen for the application, and relubrication is gotten right. So, if grease, oil and bearings keep things moving, shouldn’t you be paying more attention to what you are using and when?

For more information contact Acorn Industrial Services via email: enquiries@acorn-ind.co.uk or visit the website.