NTN-SNR ROULEMENTS, the world leader in bearings, and EFI AUTOMOTIVE, sensor specialists, commit to the motors of the future. They have revealed a sensor bearing that optimizes the control of electric motors for cars. MAGNA POWERTRAIN, a leading player in e-mobility solutions, has awarded them its first 2018 prize for innovation in the “Electrification” category. This innovation addresses a high demand from manufacturers: to find alternative solutions to existing standards. An angle sensor has been integrated into the bearing to offer a better compactness and an easier mounting. It guarantees precision measurement and safe operation.

Last November the sensor bearing was awarded the first prize in the “Supplier Innovation Challenge” in the “electrification” category. Magna Powertrain awards prizes for original equipment manufacturers’ best innovations. It has recognized the sensor bearing as a major advance for tomorrow’s vehicles. Electric and hybrid vehicles will make up to 40% of of the automotive market in 2025. NTN-SNR and EFI assert their intention to be the leaders in electric motor future developments.

Precision and reliability of Hall effect technology

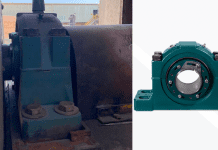

With the sensor bearing technology, NTN-SNR and EFI use the best of their respective expertise in magnetic measurement. This solution is made of a magnetic ring with an innovative pattern mounted on a high-speed ball bearing and a Hall effect sensor providing SIN/COS outputs. It measures rotor angle with 1° magnetic precision to guarantee optimal control of the electric motor.

A compact and easy-to-mount solution

Integrating the sensor function into the bearing reduces its axial space compared with existing solutions. It’s also lighter by several hundred grams, a huge gain in the current race to make vehicles lighter.

This integration also guarantees easy assembly and optimal precision after mounting, as reliable angular measurement no longer depends on the quality of the motor shaft’s mounting, as is the case for a resolver.

Unique flexibility

The sensor bearing solution can be adapted to all customer applications, regardless of the number of pairs of poles or the architecture of the electric motor. It is available in axial, radial or shaft-end configurations.

It is also possible to easily integrate a pre-charge ring and a retaining ring into the assembly, or even to have 2 sensors on the same bearing for applications requiring maximal operating safety.