While the origin of the first bearing is unknown, Ancient Egyptian drawings depict tree trunks under sleds with liquid-lubricated runners used to move massive stone blocks. While not as old as Ancient Egyptian bearings, some bearings in use today may have been produced decades ago. So, what happens when manufacturers stop producing a certain type?

Pharmaceutical supply chains must be reliable and agile, now more than ever. Traditionally drug discovery and manufacturing has been a global effort, but the impact of COVID-19 has tested supply chain resilience. A recent report by GlobalData found that 95 per cent of industry professionals were concerned about the impact of COVID-19 on company performance and 23 per cent expressed concern about supply and demand.

Pharmaceutical supply chains must be reliable and agile, now more than ever. Traditionally drug discovery and manufacturing has been a global effort, but the impact of COVID-19 has tested supply chain resilience. A recent report by GlobalData found that 95 per cent of industry professionals were concerned about the impact of COVID-19 on company performance and 23 per cent expressed concern about supply and demand.

Prior to the global disruption, technological advancement in pharmaceutical manufacturing had seen considerable change over recent decades, with new drug delivery systems, wearables, 3D printed pills and automation. Yet in this highly regulated environment, this slow and considered advancement is likely to become even slower.

Most facilities will have little choice but to opt for a more cautious approach to new technology adoption, making incremental upgrades, blending smart technology and legacy equipment that has been in service for decades.

Against this backdrop, the rate at which components face obsolescence is growing all the time making good obsolescence management crucial. If a machine is not performing optimally, it makes far more sense to replace the part that isn’t working correctly, instead of overhauling the whole system. However, sourcing spare parts could prove difficult if the component is no longer available from the original equipment manufacturer (OEM).

While it isn’t impossible to find replacement parts, it’s much easier if obsolescence management is considered from the outset. When manufacturing a pharmaceutical device, it’s important to consider the lifespan of all the components individually — even the smallest of components like bearings.

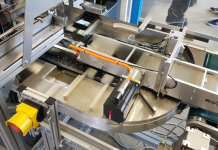

Sourcing a bearing for a hazardous area, such as a pharmaceutical application can be a challenging process, particularly if the system is an ageing one. Full ceramic bearings for example, are often used in pharmaceutical applications due to their highly corrosion resistant nature and high contamination protection.

When replacing an old bearing in an ageing pharmaceutical machine, you can’t just use any bearing. Therefore, it’s important to have strong relationships with specialist component suppliers that can keep your facility’s downtime to a minimum and costs low.

Finding a bearing supplier who can deliver the specified bearing to the same, or higher quality standards than the original and who is also willing to supply in small batch sizes is key. SMB Bearings’ fulfil this criteria and its customers can order full ceramic bearings in small volumes of around three or four bearings, even for less common types of bearings, where large bulk orders are often unnecessary for the end user.

While it might be tricky to source ancient Egyptian bearings, most bearings today aren’t in danger of becoming completely obsolete. However for aging equipment, it might take a higher level of shopping around, to source the correct replacement bearings. Building links with specialist pharmaceutical bearing suppliers should be considered as part of a wider plant obsolescence management plan.

To discuss bearing options for pharmaceutical applications further, get in touch with a reputable bearing supplier, such as SMB Bearings.

Author: Chris Johnson

Managing director at SMB Bearings