Discover in this video how COC is revolutionizing bearing technology with its game-changing Bearings — designed to outlast the competition by 2 to 3 times! In this presentation, Eiichi Kobayashi takes us inside the world of ultra-durable, smartly engineered bearings that are transforming performance standards in the power transmission industry.

From smart design to real-world success stories, this video explores:

- Why COC Bearings Live Longer: Backed by years of real-life application, COC’s bearings often last yearscompared to competitors that fail in months.

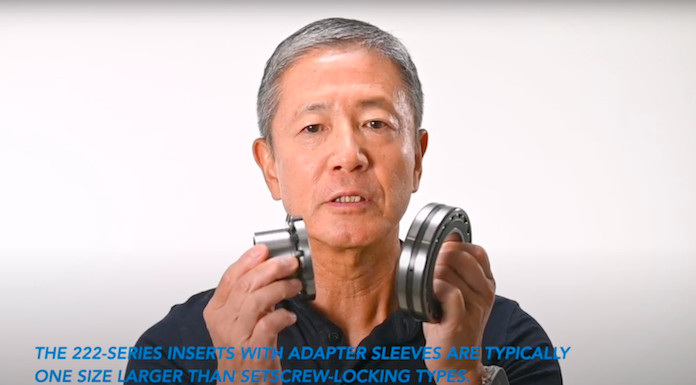

- Concentric Power with Tapered Sleeves: Say goodbye to shaft damage and vibration. The unique tapered adapter sleeve provides full 360° clamping, improving alignment and extending equipment life.

- Next-Gen Installation with Crosslock: COC’s Crosslock system eliminates traditional locking headaches. Simply tighten cap screws in a star pattern, no torque wrenches, no guesswork, no damage.

- Two Crosslock Options (CX & CXC): Whether you need a bigger insert or want to maintain the same size, COC has you covered with two solutions tailored for maximum strength and flexibility.

- Seal the Deal with Triple Lip and Non-Contaminant Technology: Advanced seals block out dust, manage heat, and protect performance, even in the harshest environments.

- Proof from the Field: AJapanese customer‘s case study slashed replacement intervals from 3 months to 5 years after switching to COC — a powerful testament to the product’s value.

Why It Matters:

COC Bearings reduce downtime, cut maintenance costs, and deliver reliable, long-term performance, making them a top choice for demanding industries. While this may shift the traditional sales model for distributors, it opens up stronger customer loyalty and long-term satisfaction.