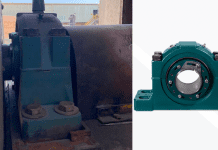

Mud motor bearings need to be carefully designed because they are called upon to deal with exceptional stresses and particularly harsh conditions

Mud motor bearings need to be carefully designed because they are called upon to deal with exceptional stresses and particularly harsh conditions

The lubrication of mud motor bearings presents particular challenges in the oil and gas exploration sector with bearing failures resulting in costly downtime. There are, however, ways to make motor bearings more reliable, as Roland Muttenthaler, Business Development Manager Oil and Gas at SKF, explains.

With many rig and crew costs totalling upwards of €200,000 a day, even the briefest disruption to production can cost oil and gas companies an eye-watering amount in lost revenue. This makes reliability the number one critical success factor in this key energy sector.

Reliability is at the core of every development in oil and gas because of its intrinsic link to productivity and therefore profitability. And nowhere is the impact on productivity felt more acutely than at the ‘sharp end’ of oil and gas exploration – the drill string (which essentially comprises the drill pipe, drill collars, tools and drill bit).

Drilling equipment must handle different geological formations including hard rock and sand so the axial and shock loads are remarkably high and there are many possible failure modes, including heavy corrosion and cracked rings.

Mud motor bearings used for oil and gas drilling must operate reliably in this exceptionally demanding environment. But the challenges don’t end there. As well as coping with severe loads, bearings for oil and gas drilling applications must be ‘lubricated’ with highly abrasive mud which contains >10% solid content such as sand. This inevitably increases abrasive wear on the rings and balls. On top of this, the mud motor bearings must contend with harsh chemical additives such as chlorides.

Lubrication of mud motor bearings is relatively straightforward – mud is pressurized to around up to 10,000 psi (690 bar) and pumped through the downhole drill string. It passes through the motor, lubricates the bearing stack, then passes through the drill bit and pushes outside the drill string, taking the drilling debris with it back to the surface. The mud and debris are then screened and filtered on the drill rig before being pumped back down the hole in a closed-loop operation.

For many years, the drill bit has been the ‘weak link’ in the drill string in terms of productivity so development work has concentrated on this area. As a result of improvements in drill bit performance and motor power section, the ‘weak link’ has moved onto the bearing. This prompted SKF to apply its extensive capabilities in failure analysis, materials engineering and testing and design to pioneer new mud motor bearings that allow for a significant increase in mean time between failures (see the box).

The challenges for us as a manufacturer include using special materials such as wear-resistant steels. And, although it is starting to recover slowly, the price of crude oil has fallen dramatically in recent years. This is at a time when the cost of drilling for, and extracting, oil remains high so the big players are looking for ways to optimize every piece of equipment – including the mud motor bearings – to maximize efficiency and minimize operating costs.

A typical SKF mud motor contains between eight and 12 rows of bearings. When the bearing is new, most of the load is taken by the first few rows. As each row begins to wear, the load is shifted to the next row and the next until all the rows are worn equally. Then, the load is shifted back to the first row and the process is repeated.

Because every situation is different, SKF brings to bear a specific set of tools to customize the mud stack bearings for each project depending on space limitations, fluctuating demands in drilling operations, depth and direction of drilling and geological conditions. These tools include in-house testing, some field testing, and reviewing process and operating parameters; the box explains more on this.

With a predicted surge in worldwide drilling activity over the coming years, increased reliability will translate to extended mean time before failure and the improved performance offered by companies like SKF provides a critical advantage for oil producers looking to gain an edge in this ferociously competitive market.

BOX

The SKF design process

To improve bearing performance and reliability in oil and gas exploration applications, SKF engineers have used the company’s own proprietary design and simulation tools to:

• Accurately define the behaviour of a bearing stack.

• Redesign the bearing to minimize stresses and optimize load-carrying capacity.

• Test new designs and materials.

Precise bearing load analysis is impossible in a ‘live’ working environment because the drill head can’t be accessed during operation. However, SKF has built a test rig that simulates basic operating conditions of mud stack bearing components to investigate ways to resolve the problem of premature bearing failure. Using these rigs, the company has been able to replicate wear patterns and cracking in the rings in a manner consistent with typical failure modes.

The SKF methodology, however, goes beyond bearing analysis, encompassing a review of the total application and operating environment. A unique SKF competency is its depth of knowledge of materials development, particularly steel.

An initial root cause failure analysis conducted by SKF engineers showed that the base steel as well as post-production processes would have a significant impact on bearing service life.

SKF manufactured a limited number of bearings of the new design for the test rig. As well as the special steel for improved wear-resistance , the bearings featured a full complement of balls for increased load-carrying capacity, interchangable rings for optimized load distribution and a unique internal geometry to support heavy axial drilling loads and resist contaminants.

After the positive results on the SKF test rigs, the bearings were put into operation on a customer field job. The bearings were assessed during standard service intervals of the drilling motor and were found to be in a useable condition and were sent back for additional runs. Through bearing design changes and an optimized motor overhaul procedure, the run hours have been improved in this specific case by around 100%.

Expectations are that the SKF mud motor bearing solution will perform in downhole conditions significantly longer than the industry’s current 50-200hrs service hours.