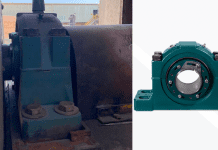

In 2021 Bowman International, a manufacturer of bearings and allied components, disrupted the split roller bearing market with a new product innovation containing 3D printed components – a design evolution that enabled Bowman’s engineers to bring to market a world-first, high-load capacity split roller bearing.

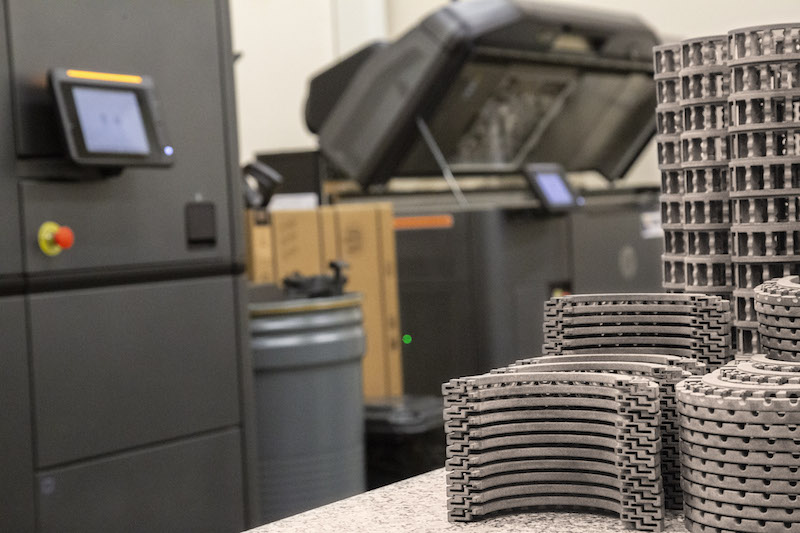

By combining its knowledge of bearings, with its inhouse production 3D printing capabilities, Bowman has since developed a range of complex and niche bearing cages for applications all over the world.

By combining its knowledge of bearings, with its inhouse production 3D printing capabilities, Bowman has since developed a range of complex and niche bearing cages for applications all over the world.

Here, Charan Prakash, Applications Engineer for Bowman’s Additive Production division, explains how production 3D printing is transforming how we think about bearing cage design:

Bearings encompass a highly diverse range of components and finding the right design that not only optimises the performance but also eases manufacturability is challenging. This is especially important for more challenging environments, where perhaps bearing installation is difficult, legacy parts are no longer available on the open market, or there are high technical specifications that make off-the-shelf solutions unviable. These are the real industry issues we like to solve.

Until recently, the bearing industry designed cages within the confines of what was physically and financially possible using traditional manufacturing techniques and standard components, but production 3D printing has removed many of these boundaries.

Broadening the horizons for cage complexity and performance

3D printing increases the scope for component design, by making easy work of complex geometries that simply aren’t achievable using production techniques. This allows us to recreate legacy parts for niche sectors, design bespoke bearing solutions for emerging markets and innovate performance-driven, production-volume 3D printed cages that, in many instances, perform better than conventional products. All of this is available in lower batch numbers, with incredibly short lead times and no upfront tooling costs.

Since innovating our own 3D printed cages to increase axial and radial load performance in a split roller bearing, we have supported the global bearing supply chain in overcoming a range of cage design issues.

Since innovating our own 3D printed cages to increase axial and radial load performance in a split roller bearing, we have supported the global bearing supply chain in overcoming a range of cage design issues.

Let us examine a few use cases that really showcase the capabilities of this technology:

Use case example: Easier installation thanks to 3D printed PA11

Overcoming difficult installation scenarios is a common challenge and was in fact, a secondary consideration for our own split bearing innovation.

Another example came when we designed two simple needle roller bearings for the automotive sector – the smaller of the two being in a hard-to-reach location. Understanding that our printing material, PA11 is highly flexible, we engineered a split in the bearing that would allow the installer to simply stretch out the bearing and snap it around the shaft – a quick and uncomplicated solution that simply would not be possible when manufacturing with metal. An important consideration when designing this product was ensuring that the pockets responsible for holding the rollers in place, would continue to do so as the product was outstretched and snapped around the shaft.

Another example of leveraging 3D printing for easy bearing cage installation came from the US, when a customer asked us to redesign their product to accommodate a change in installation process. The original metal component comprised two cages that clipped together from either side, but Bowman AP was able to re-engineer the entire part into just one piece that fastened on one side only, making installation faster and more cost efficient.

Another example of leveraging 3D printing for easy bearing cage installation came from the US, when a customer asked us to redesign their product to accommodate a change in installation process. The original metal component comprised two cages that clipped together from either side, but Bowman AP was able to re-engineer the entire part into just one piece that fastened on one side only, making installation faster and more cost efficient.

Using 3D printing, our design engineers were able to create a range of iterations and prototypes within a very short two-week timeframe, requiring no upfront tooling costs. A new design was quickly agreed, successfully tested.

Use case example: Serving niche sectors with small batches

3D printing is growing in popularity within niche applications and sectors that find mainstream supply lines unable to produce a viable solution.

Recently, we have worked on solutions for several older bearing designs, in sizes that are no longer readily available for niche sectors that require smaller batches. But, instead of simply replicating the old product, we took our usual engineering approach to component design and improved its performance with better designed roller pockets before reproducing it in small, frequent batches.

Our engineering expertise comes at no extra cost and is one of the things that sets us apart from the large scale “print houses” that dominate the 3D printing marketplace.

Our engineering expertise comes at no extra cost and is one of the things that sets us apart from the large scale “print houses” that dominate the 3D printing marketplace.

Use case example: Performance enhancing characteristics

In many recent designs we have successfully leveraged the capabilities of 3D printing to enhance the performance of the cages we produce. From increasing load capacity and improving L10 bearing life, to creating cages that require less frequent lubrication.

Without the limitations of traditional manufacturing processes or tooling, we are able to design cages that accommodate an increased number of rollers or balls to improve overall performance and uptime.

Without the limitations of traditional manufacturing processes or tooling, we are able to design cages that accommodate an increased number of rollers or balls to improve overall performance and uptime.

This is a concept we used for our own high-load capacity split roller bearings, as well as series of small strip roller bearings produced for the medical sector, where we improved the design of the pockets so that they could hold the ball bearings in place more effectively to improve overall bearing performance.

Now is the right time to explore production 3D printing

Gone are the days where 3D printing was a technique reserved solely for prototyping and hobbyists. The production 3D printing market is growing at a rapid pace, and while it is still in its infancy, it is important to select an established production 3D printing partner that offers an engineering approach to component design, rather than a print and post solution.

Leveraging Bowman’s undeniable expertise in the bearing sector, Bowman Additive Production is becoming a favoured service provider to OEMs and bearing manufacturers looking to harness the benefits of this modern production method. And in today’s economy, broadening the scope of design for bearing cages is not the only appealing benefit.

As material costs rise and lead times get longer, our ability to eliminate upfront tooling costs and guarantee short lead times of around two weeks, is fuelling the shift towards using 3D printing for component design and manufacture. Far lower minimum order quantities free up investment capital, and lower stock volumes means less transportation costs and less reliance on warehousing too.

Using 3D printing as a solution for bearing cage design is a trend that shows no sign of slowing, and off the back of its own successes, Bowman International is now leading the migration towards faster, cost-effective, performance-driven, 3D-printed bearing component design.

For more information on how Bowman Additive Production can support your next design challenge, visit the website or call 01235 462 500.