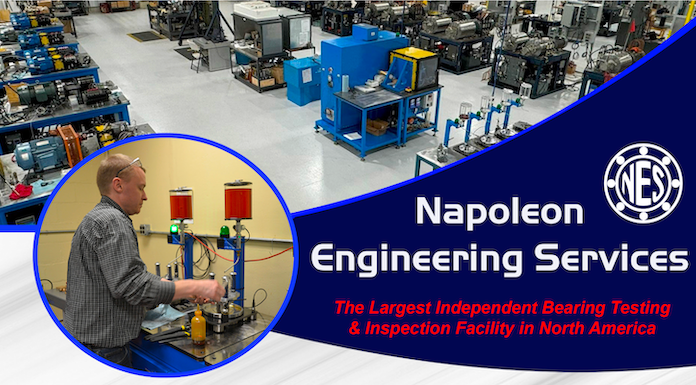

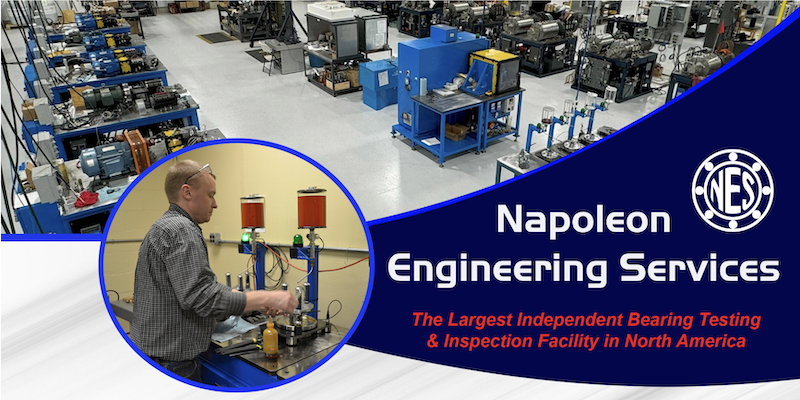

Napoleon Engineering Services (NES) continues to strengthen its position as one of North America’s most capable independent bearing testing organizations, offering both Standard Bearing Testing (SBT) and Environmental Testing to help manufacturers and end users qualify suppliers with confidence.

NES operates the largest independent bearing testing and inspection facility in North America, with the capacity to run multiple test programs simultaneously. This enables companies to compare suppliers, validate new bearing sources, and reduce risk when switching or qualifying alternative products.

What Standard Bearing Testing Delivers

NES’ Standard Bearing Testing program is designed to generate statistically meaningful performance data by testing bearings under controlled and repeatable conditions. SBT allows customers to:

- Correlate new suppliers against existing, approved suppliers

- Maximize the use of test equipment through standardized setups

- Test larger sample sizes for stronger statistical confidence

- Apply both classical life testing and sudden-death test methods

- Establish L10 life confidence bands based on real test data

Standard Bearing Testing is performed on the bearing itself, typically without application-specific components. Load, speed, temperature, and lubrication conditions can be adjusted, but the goal is to create accelerated and repeatable test conditions that allow direct comparison between products. Fatigue-related bearing failure is the measurable output, enabling Weibull life analysis and objective supplier benchmarking.

According to NES President and Chief Engineer Chris Napoleon:

“By performing standard bearing testing, NES can inform customers about the design and manufacturing quality of bearings, resulting in reduced risk when qualifying new or alternative suppliers. The detailed results provide the information needed to make sound sourcing decisions.”

Environmental Testing for Contamination and Seal Performance

In many real-world applications, bearings do not fail from fatigue alone. Contamination, moisture, and debris intrusion are often the dominant failure modes. NES’ Environmental Testing services are designed to evaluate how well bearing seals protect the internal bearing cavity in these demanding conditions.

Environmental testing is particularly relevant for applications such as:

- Off-highway vehicles

- Agricultural and heavy equipment

- Off-road motorsports

- Commercial and consumer outdoor power equipment

- Turf maintenance systems

NES uses mud slurry rigs and dust box platforms to simulate harsh operating environments and measure how effectively seals prevent contaminants from entering the bearing and shortening its service life.

High-Capacity Testing Infrastructure

NES operates more than 50 endurance test rigs covering a wide range of bearing sizes and types, allowing multiple supplier evaluations and development programs to run in parallel. This high level of capacity enables faster project turnaround and helps customers respond quickly to challenges related to cost, quality, tariffs, or supply chain disruptions.

By combining standard life testing with environmental performance validation, NES provides a complete picture of how bearings will perform both in controlled conditions and in real-world operating environments.

For manufacturers and equipment builders facing sourcing uncertainty or evaluating new suppliers, NES’ testing services provide an independent, data-driven foundation for making confident decisions.

Contact:

Email: sales@nesbearings.com; cnapoleon@nesbearings.com

Phone: (877) 870-3200

Website: www.nesbearings.com