In April 2024, NSK Ltd., a global leader in bearing technology, unveiled its 7th generation of low-friction tapered roller bearings, marking a significant advancement in automotive and mobility applications. Designed to enhance fuel and electricity efficiency, these bearings are poised to play a critical role in the evolving landscape of internal combustion engine (ICE), hybrid electric vehicle (HEV), plug-in hybrid electric vehicle (PHEV), and electric vehicle (EV) technologies. At Baker Bearing Company, we’re excited to explore how this innovation aligns with our commitment to delivering high-performance solutions for our customers.

Driving Efficiency Through Innovation

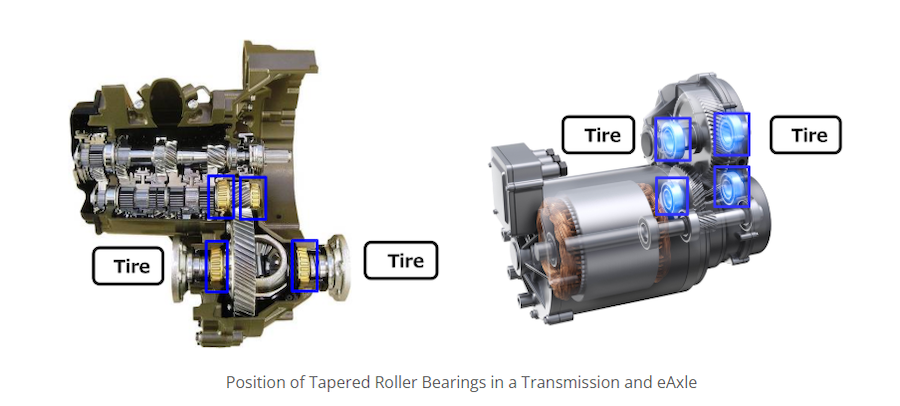

NSK’s latest tapered roller bearings are engineered to reduce friction by an average of 20% across the entire rotation speed range, a breakthrough that directly contributes to improved vehicle range and energy efficiency. Tapered roller bearings are commonly used in automotive applications, particularly in high-load, low-rotation-speed conditions such as on the tire side of transmissions and eAxles. By optimizing the number of rollers, NSK has achieved a significant reduction in rolling friction, addressing the growing demand for enhanced powertrain efficiency in a decarbonizing world.

This development is especially timely given the global push toward sustainability. With the automotive industry rapidly transitioning to electrification, reducing friction in critical components like tapered roller bearings is essential for extending the range of EVs and improving fuel economy in ICE and hybrid vehicles. NSK’s innovation supports these goals by minimizing energy loss, enabling smaller and lighter gearbox designs, and enhancing overall drivetrain performance.

This development is especially timely given the global push toward sustainability. With the automotive industry rapidly transitioning to electrification, reducing friction in critical components like tapered roller bearings is essential for extending the range of EVs and improving fuel economy in ICE and hybrid vehicles. NSK’s innovation supports these goals by minimizing energy loss, enabling smaller and lighter gearbox designs, and enhancing overall drivetrain performance.

A Legacy of Friction Reduction

NSK has been a pioneer in low-friction bearing technology since the 1980s, consistently refining its designs to meet the evolving needs of the automotive sector. The 7th generation bearings build on this legacy, incorporating advanced optimization techniques that leverage NSK’s expertise in special crowning technology and cage design for lean lubrication conditions. These advancements not only reduce friction but also address challenges such as excessive surface pressure and seizure at roller ends, ensuring durability and reliability under demanding conditions.

The bearings are also highly durable against contamination, with NSK confirming through testing that their service life exceeds calculated expectations. This durability, combined with a 20% average friction reduction, makes the 7th generation bearings a versatile solution for various mobility applications, from traditional ICE vehicles to cutting-edge EVs.

Market Impact and Future Outlook

NSK’s 7th generation low-friction tapered roller bearings are designed to be produced using existing manufacturing facilities, allowing for rapid market adoption. As the automotive industry continues to prioritize energy efficiency and sustainability, these bearings are well-positioned to meet the needs of manufacturers seeking to enhance vehicle performance while reducing environmental impact.

The introduction of these bearings aligns with global standards like the Worldwide Harmonized Light Vehicles Test Cycle (WLTC), adopted in Japan in 2017, which measures fuel economy across various driving conditions. By delivering low friction across the entire rotation speed range, NSK’s bearings help automakers meet stringent fuel economy and emissions standards, making them a valuable asset in the pursuit of a carbon-neutral society.

The 7th generation low-friction tapered roller bearings represent a significant step forward to deliver products that enhance performance, reliability, and efficiency. Whether you’re an automotive manufacturer looking to optimize your powertrain or a mobility innovator pushing the boundaries of EV technology, these bearings offer a proven solution to drive your success.

As we move toward a more sustainable future, NSK’s latest innovation is a testament to the power of engineering excellence, and we’re excited to bring these benefits to our customers.

Citations

– NSK Develops 7th Generation Low-Friction Tapered Roller Bearings | NSK Global. www.nsk.com

– NSK Develops 7th Generation Low-Friction Tapered Roller Bearings – BEARING NEWS. www.bearing-news.com

Source: Baker’s Bearing Report