By: Andreas Winkler, Max Marian, Stephan Tremmel and Sandro Wartzack

Engineering Design, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Martensstr. 9, 91058 Erlangen, Germany; tremmel@mfk.fau.de (S.T.); wartzack@mfk.fau.de (S.W.)

* Correspondence: winkler@mfk.fau.de (A.W.); marian@mfk.fau.de (M.M.)

Abstract

1. Introduction

According to Holmberg and Erdemir [1], tribological contacts account for about 23% of the world’s total energy consumption, whereas overcoming friction contributes to about 20% and remanufacturing worn parts and spare equipment due to wear and wear-related failures amount to 3%. By utilizing new surface, material and lubrication technologies for friction reduction and wear protection in vehicles, machines and other equipment, energy losses could be reduced by up to 40% [1]. However, wear gets increasingly promoted by the expanding use of low-viscosity lubricants and the tendency of operating in the friction optima in the mixed lubrication regime [2]. Moreover, wear can be considered critical as it can lead to catastrophic failures and breakdowns, thus having a negative impact on productivity and costs. Therefore, appropriate numerical modeling over different scales and predicting wear in a reliable manner offers new possibilities for understanding and redesigning tribological systems in machine elements or engine components. Consequently, the comprehension and simulation of wear in tribo-contacts were the subject of several studies ranging from boundary to hydro-(HL) or elastohydrodynamically lubricated (EHL) contacts.

Thereby, Podra et al. [3,4] numerically investigated the wear of a dry pin-on-disc and a conical spinning contact based upon the Archard [5] wear model. The calculation of the contact pressure was accomplished using the finite element method (FEM) and by means of the Winkler surface model [6]. Hegadekatte et al. [7,8] also examined the wear of a pin-on-disc contact based upon the FEM and the Archard model, however considered local wear by shifting the nodes of an adaptive mesh in the normal direction. Andersson et al. [9] investigated the wear of a dry sphere on flat contact. The contact pressure was calculated by a discrete convolution and fast Fourier transformation (DC-FFT) method utilizing the half-space theory and assuming linear elastic–perfectly plastic material behavior as described by Liu et al. [10]. Ashraf et al. [11] implemented a FEM-based wear simulation for a dry composite alloy contact using a free-mesh. Sfantos et al. [12] suggested a boundary element formulation for three-dimensional dry sliding wear based on Archard’s model, which was applied to a pin-on-disc contact as well as to a hip arthroplasty wear problem. As aforementioned approaches did not take deterministic surface topography into account, Terwey et al. [13,14] implemented a contact and wear model based upon the half-space theory for boundary lubricated thrust roller bearings, considering surface roughness. Thereby, the wear coefficient of Archard’s law was determined using continuum damage mechanics (CDM). A comparison with test rig experiments revealed that the severe wear regime could not be satisfactorily described, whereas the good agreement of numerical prediction and test results was achieved for mild wear.

2. Numerical Modeling

For the numerical wear calculation of a rolling element and raceway in a thrust roller bearing, a full-system finite element modeling (FEM) approach for EHL contacts was expanded by a mixed lubrication model as well as a local Archard type wear model to describe the surface topography evolution. The calculation model was part of the computation software TriboFEM. The investigated tribo-system as well as the main physical and numerical characteristics are thoroughly described and reasoned below.

2.1. Load Cases, Material and Lubricant Properties

In order to allow qualitative comparability with the experimental results from literature, the wear calculations were carried out by means of a thrust roller bearing 81212. Four load cases with the speeds, simulated test durations, axial loads and initial Hertzian pressures in the roller/raceway contact (assuming a pure line contact, i.e., without profiling) according to Table 1 were studied. Thus, each washer surface element experienced a constant number of 2,850,000 overrollings.

Moreover, a realistic velocity distribution was taken into account, whereby u1 was considered as the relative velocity of the washer in the rolling x direction:

![]()

The roller maintained a constant peripheral speed of:

Perpendicular to the rolling direction, the washer had a relative velocity of:

![]()

whereas the roller had no velocity component in the y direction:

![]()

Underlying geometry and coordinates are illustrated in Figure 1.

Density and viscosity were considered to be pressure-dependent following the equations from Dowson and Higginson [38] and Roelands [39], respectively:

Shear-thinning and thermal effects were neglected within the scope of this study and are subject of on-going research work.

2.2. Asperity Contact Model

and the mean summit radius:

and the mean summit radius:

The distance between the mean height of the asperities and the mean height of the surface according to Bush et al. [51] was:

Finally, the relation between the separation of a rough surface and a flat surface based on the asperity heights and surface heights reads:

Finally, the relation between the separation of a rough surface and a flat surface based on the asperity heights and surface heights reads:

2.3. EHL Modeling

is solved in its weak form on the upper surface Ωc of the elastically deformed equivalent body (Figure 2) to describe the lubricant’s hydrodynamics. The first term describes the influence of the pressure gradient, while the second one accounts for the boundary velocities of the contacting bodies and the wedge-shape of the lubricant gap. Zero pressure boundary conditions were applied at the in- and outlet. A mass-conserving algorithm, as introduced by Marian et al. [58], dealt with cavitation effects. Therefore, the lubricant’s density and viscosity were multiplied with the fractional film content. The latter was defined as the ratio of the lubricant layer to the gap height:

is solved in its weak form on the upper surface Ωc of the elastically deformed equivalent body (Figure 2) to describe the lubricant’s hydrodynamics. The first term describes the influence of the pressure gradient, while the second one accounts for the boundary velocities of the contacting bodies and the wedge-shape of the lubricant gap. Zero pressure boundary conditions were applied at the in- and outlet. A mass-conserving algorithm, as introduced by Marian et al. [58], dealt with cavitation effects. Therefore, the lubricant’s density and viscosity were multiplied with the fractional film content. The latter was defined as the ratio of the lubricant layer to the gap height: with the penalty factor γ(ph), which is zero if ph < 0, otherwise γ(ph) = ξ, where ξ is a sufficiently high algebraic number. The Galerkin least squares (GLS) method (Hughes et al. [59]) and isotropic diffusion (Zienkiewicz et al. [60]) were utilized for the numerical stabilization.

with the penalty factor γ(ph), which is zero if ph < 0, otherwise γ(ph) = ξ, where ξ is a sufficiently high algebraic number. The Galerkin least squares (GLS) method (Hughes et al. [59]) and isotropic diffusion (Zienkiewicz et al. [60]) were utilized for the numerical stabilization.

Based upon the FEM, the elastic problem was calculated for one body Ω with the equivalent Young’s modulus:

and Poisson’s ratio: by applying the linear elasticity equation:

by applying the linear elasticity equation:

describes the height of the separating fluid film in terms of the distance and the shape of the undeformed geometry as well as of the elastic deformation. The geometry of the rolling element was composed of a quadratic approximation of the radius in and the logarithmic profile perpendicular to the direction of motion:

describes the height of the separating fluid film in terms of the distance and the shape of the undeformed geometry as well as of the elastic deformation. The geometry of the rolling element was composed of a quadratic approximation of the radius in and the logarithmic profile perpendicular to the direction of motion:

In addition, the computational domain was decreased in y direction by the factor scale in order to reduce the number of degrees of freedom and thus the computation time.

2.4. Wear Modeling

Widely used wear models were proposed by Kragelski [62] and Fleischer et al. [63]. The first developed a molecular mechanical fatigue-based wear model and the approach of the latter considered the frictional energy density. However, the most common model for calculating wear, originally intended for dry contacts, goes back to Archard [5,64] and Holm [65]. Although various other wear modeling approaches, based upon empirical relationships or limited to specific applications, exist in the literature, Archard’s wear model was applied within the scope of this contribution for its generality and simplicity. Thereby, the total wear volume Vw was considered proportional to the normal force FN, the sliding distance s and the proportionality factor k, also known as the wear coefficient:

Since the wear coefficient depends on numerous factors, such as material properties, surface conditions and boundary layers, it was frequently determined experimentally and could vary between 10−1 and 10−15 mm3/Nm for metals [66,67]. As it can be assumed that even under the highest loads, some protecting boundary layer will be formed and that at least some lubricant will remain in the contact between the two opposing asperities, it seems appropriate in the context of the present study to apply a wear coefficient that is valid for the boundary lubrication regime in order to calculate the wear depth. In accordance to Czichos and Habig [68], a local wear coefficient of k¯=6×10−8 mm3/Nm was applied.

2.5. Surface Topography Model

The Sugimura model [32,33,34] was used to take into account the wear-induced change of statistical surface parameters within the asperity contact pressure calculation.

where:

where:

Thereby, ψ denotes the probability density function of the wear-induced height loss and could be derived from the wear particle size distribution:

where u, v, and w are the wear particle dimensions. Additionally, f(u,v,w) denotes the probability density function of the wear particle size. Assuming the proportionality of u and v to w results in:

where u, v, and w are the wear particle dimensions. Additionally, f(u,v,w) denotes the probability density function of the wear particle size. Assuming the proportionality of u and v to w results in:

with the marginal density function of the wear particle density function:

Following Kimura and Sugimura [34], an exponential distribution for the wear particle size, as depicted in Figure 3b, was assumed. Finally, the fraction of the removed surface PDF was then redistributed to the remaining density function accordingly (Figure 3a). The surface height probability density function at the time t + Δt was written by considering the shift of the mean height Δz0:

where the shift of the mean height satisfies:

2.6. Overall Numerical Procedure

3. Results and Discussion

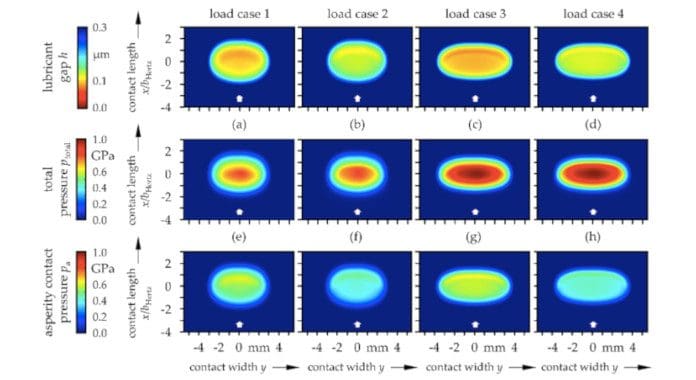

Due to the roller radius in and the logarithmic profile perpendicular to the direction of motion, the initial conditions featured typical characteristics for elliptical EHL contacts with a horseshoe-shaped lubricant gap (Figure 5a–d), a total pressure distribution similar to Hertz (Figure 5e–h) as well as a constriction in the film height as well as a barely pronounced Petrusevich spike in the outlet region. Due to the smaller contact area, the pressures exceeded the Hertzian values determined for a perfect line contact (Table 1). In addition, the speed profile (Figure 1b) resulted in a slight asymmetry and tilting of the contact area. The clearly recognizable asperity contact pressure (Figure 5i–l) followed the lubricant height in shape and indicated an operation under mixed EHL conditions. The effects of the load case and oil on the lubricant gap and the pressure formation basically corresponded to theoretical expectations.Higher speed (load case 2) and higher viscosity (Figure 6) led to a larger and higher load (load case 3, 4) to a lower fluid film height. Accordingly, the asperity contact pressure behaved just oppositely. Moreover, the higher load led to a significantly larger elastically deformed contact area. It should be noted that although the contact width y was scaled in the same way for all cases, the contact length x was plotted normalized to the Hertzian width for reasons of reduced space requirements. Thus, the contact area actually expanded further in the x direction at higher loads as well.

The continuous progress of the simulated time led to material loss and changes of the surface topography of the washers and the rollers. In brief, the wear-depth distribution, as depicted in Figure 7, followed the product of asperity contact pressure and sliding velocity. The inner (negative y values) and outer halves (positive y values) of the raceway showed a slightly asymmetrical shape due to different velocities. Thereby, wear was higher in the area of the negative slip. This stands in good agreement with the experimental results from Terwey et al. [13,14]. Despite differences in absolute values due to the less severe conditions (lower loads and higher velocities) and the operation being in the mixed instead of the boundary lubrication regime, the qualitative profiles agree well. Furthermore, a more significant difference in the wear depth between the inner and outer halves of the raceway could be found on the washer. This was due to the fact that the calculated wear volume was distributed over a smaller circumference at the inner half of the raceway than at the outer area. Higher loads and lower sliding velocities resulted in a higher wear depth. This can be explained by lower lubricating film heights resulting in higher asperity contact pressures. For the same reason, the use of a lower viscosity oil (FVA1) compared to a higher viscosity oil (FVA 2) led to higher wear depths.

The PDF of the asperity heights were further applied to the calculation of the asperity contact pressures, which were a prerequisite for the application of the mixed friction model based upon the load sharing concept. As can be seen in Figure 9, the contact pressures were shifted to the bottom left with increasing simulation time, which was caused by the worn-out asperity peaks in terms of the modified probability density functions.Furthermore, in most cases the asperity contact pressure curves also reached a stationary state with slight differences to the final state being distinguishable for less harmful cases, see for example Figure 9f).

Changes in the surface topography were also accompanied by transformations of the lubrication conditions, see Figure 10, Figure 11, Figure 12 and Figure 13. In addition to the horseshoe-shaped constriction of the lubricant gap at the contact outlet region, there was a similarly pronounced minimum along the y = 0 axis. This was due to the low wear in this area, despite the high total and asperity contact pressure, since the conditions of the pure rolling (slide-to-roll ratio (SRR) = 0) prevailed. Furthermore, the asymmetry and slight tilting resulting from the speed and wear profiles could still be observed. Generally, the distributions of the lubricant gap and the pressure continued to correspond to the principles of the influences of speed, load and viscosity. In most cases, the fluid and pressure distribution only featured small differences between the half and end of the simulation time. While some load cases still showed significant asperity contact pressure after the simulated runtime, see Figure 12i,k), others indicated a kind of completed running-in process with hardly any solid contact compared to the initial state, see for example Figure 13l).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| bHertz | Hertzian contact half-width |

| C | compliance matrix |

| d | separation based on asperity heights |

| D | diameter of roller |

| E’ | reduced Young’s modulus |

| E1, E2 | Young’ modulus of washer/roller |

| Eeq | equivalent Young’s modulus |

| f | probability density function of the wear particle size |

| fw | marginal density function of the wear particle density function |

| F | bearing load |

| FN | normal contact force |

| h | lubricant gap |

| h0 | film thickness constant parameter |

| hliq | lubricant film thickness |

| hw | local wear depth |

| H | dimensionless lubricant gap |

| k | global wear coefficient |

| k¯ | local wear coefficient |

| L | length of roller |

| m0,2,4 | zeroth, second and fourth spectral moment of a surface profile |

| n | rotational speed |

| pa | asperity contact pressure |

| ph | fluid pressure |

| pHertz | Hertzian contact pressure |

| ptotal | total pressure |

| P | dimensionless pressure |

| Rx | radius of curvature in x direction |

| s | sliding distance |

| s0 | geometry-function of the roller |

| SRR | slide-to-roll ratio |

| t | test duration |

| u, v, w | size of cuboid shaped wear particle |

| u1,u2 | relative velocity of the washer/roller in x direction |

| U | displacement tensor |

| Uz | displacement in z direction |

| v1,v2 | relative velocity of the washer/roller in y direction |

| vslip | slip velocity |

| Vw | wear volume |

| w¯¯¯ | mean height loss |

| W | mean wear depth |

| x,y | coordinates in and perpendicular to the rolling direction |

| X, Y | dimensionless coordinates in and perpendicular to the rolling direction |

| ys | distance between the mean height of asperities and the mean height of surface |

| z | profile coordinate based on mean height of surface |

| zs | profile coordinate based on mean height of asperities |

| z0 | ordinate of the mean line of the composite profile |

| Δz0 | descending quantity of mean line |

| zh | highest point of composite profile |

| Δzh | moving distance of highest point |

| α | bandwidth parameter |

| αp | pressure-viscosity coefficient |

| β | mean summit radius |

| γ | penalty function |

| δelastic | elastic deformation in z direction |

| δ¯elastic | dimensionless elastic deformation in z direction |

| ε | strain tensor |

| ν1, ν2 | Poisson’s ratio of washer/roller |

| νeq | equivalent Poisson’s ratio |

| ρ | lubricant density |

| ρ¯ | dimensionless lubricant density |

| ρ0 | lubricant density at reference state (40 °C) |

| η | lubricant viscosity |

| η¯ | dimensionless lubricant viscosity |

| η0 | lubricant viscosity at reference state (40 °C) |

| ηs | area density of asperities |

| θ | fractional film content |

| σ | standard deviation of surface heights |

| σelastic | stress tensor of the equivalent body |

| σs | standard deviation of asperity heights |

| ϕ | probability density function of surface heights |

| ϕs | probability density function of asperity heights |

| ψ | height-loss probability density function |

| ω | angular velocity |

| Ωc | contact domain |

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Põdra, P.; Andersson, S. Simulating sliding wear with finite element method. Tribol. Int. 1999, 32, 71–81. [Google Scholar] [CrossRef]

- Põdra, P.; Andersson, S. Wear simulation with the Winkler surface model. Wear 1997, 207, 79–85. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Winkler, E. Die Lehre von der Elasticitaet und Festigkeit: Mit Besonderer Rücksicht auf Ihre Anwendung in der Technik für Polytechnische Schulen, Bauakademien, Ingenieue, Maschinenbauer, Architecten, etc; Dominicus: Prague, Austria-Hungary, 1868. [Google Scholar]

- Hegadekatte, V.; Huber, N.; Kraft, O. Modeling and simulation of wear in a pin on disc tribometer. Tribol. Lett. 2006, 24, 51–60. [Google Scholar] [CrossRef]

- Hegadekatte, V.; Kurzenhäuser, S.; Huber, N.; Kraft, O. A predictive modeling scheme for wear in tribometers. Tribol. Int. 2008, 41, 1020–1031. [Google Scholar] [CrossRef]

- Andersson, J.; Almqvist, A.; Larsson, R. Numerical simulation of a wear experiment. Wear 2011, 271, 2947–2952. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q.; Liu, G. A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 2000, 243, 101–111. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Ahmed, R.; Ali, O.; Faisal, N.H.; El-Sherik, A.M.; Goosen, M.F.A. Finite Element Modeling of Sliding Wear in a Composite Alloy Using a Free-Mesh. J. Tribol. Trans. ASME 2015, 137, 27. [Google Scholar] [CrossRef]

- Sfantos, G.; Aliabadi, M. A boundary element formulation for three-dimensional sliding wear simulation. Wear 2007, 262, 672–683. [Google Scholar] [CrossRef]

- Terwey, J.T.; Berninger, S.; Burghardt, G.; Jacobs, G.; Poll, G. Numerical Calculation of Local Adhesive Wear in Machine Elements Under Boundary Lubrication Considering the Surface Roughness. In Proceedings of the 7th International Conference on Fracture Fatigue and Wear; Abdel Wahab, M., Ed.; Springer: Singapore, 2019; pp. 796–807. ISBN 978-981-13-0410-1. [Google Scholar]

- Terwey, J.T.; Fourati, M.A.; Pape, F.; Poll, G. Energy-Based Modelling of Adhesive Wear in the Mixed Lubrication Regime. Lubricants 2020, 8, 16. [Google Scholar] [CrossRef]

- Zhu, N.; Martini, A.; Wang, W.; Hu, Y.; Lisowsky, B.; Wang, Q.J. Simulation of Sliding Wear in Mixed Lubrication. J. Tribol. 2007, 129, 544–552. [Google Scholar] [CrossRef]

- Zhu, N.; Hu, Y.-Z. A Computer Program Package for the Prediction of EHL and Mixed Lubrication Characteristics, Friction, Subsurface Stresses and Flash Temperatures Based on Measured 3-D Surface Roughness. Tribol. Trans. 2001, 44, 383–390. [Google Scholar] [CrossRef]

- Hu, Y.-Z.; Zhu, N. A Full Numerical Solution to the Mixed Lubrication in Point Contacts. J. Tribol. 1999, 122, 1–9. [Google Scholar] [CrossRef]

- Lorentz, B.; Albers, A. A numerical model for mixed lubrication taking into account surface topography, tangential adhesion effects and plastic deformations. Tribol. Int. 2013, 59, 259–266. [Google Scholar] [CrossRef]

- Reichert, S.; Lorentz, B.; Heldmaier, S.; Albers, A. Wear simulation in non-lubricated and mixed lubricated contacts taking into account the microscale roughness. Tribol. Int. 2016, 100, 272–279. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Beheshti, A.; Khonsari, M.M. A Thermodynamic Approach for Prediction of Wear Coefficient Under Unlubricated Sliding Condition. Tribol. Lett. 2010, 38, 347–354. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Khonsari, M.M. Thermoelastohydrodynamic Analysis of Spur Gears with Consideration of Surface Roughness. Tribol. Lett. 2008, 32, 129–141. [Google Scholar] [CrossRef]

- Beheshti, A.; Khonsari, M.M. An engineering approach for the prediction of wear in mixed lubricated contacts. Wear 2013, 308, 121–131. [Google Scholar] [CrossRef]

- Hao, L.; Meng, Y. Numerical Prediction of Wear Process of an Initial Line Contact in Mixed Lubrication Conditions. Tribol. Lett. 2015, 60, 443. [Google Scholar] [CrossRef]

- Chang, W.-R.; Etsion, I.; Bogy, D.B. An Elastic-Plastic Model for the Contact of Rough Surfaces. J. Tribol. 1987, 109, 257–263. [Google Scholar] [CrossRef]

- Zhang, Y.; Kovalev, A.; Hayashi, N.; Nishiura, K.; Meng, Y. Numerical Prediction of Surface Wear and Roughness Parameters During Running-In for Line Contacts Under Mixed Lubrication. J. Tribol. Trans. ASME 2018, 140, 061501. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of Average Flow Model to Lubrication Between Rough Sliding Surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. Elastic-Plastic Contact Analysis of a Sphere and a Rigid Flat. J. Appl. Mech. 2002, 69, 657–662. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. A Finite Element Based Elastic-Plastic Model for the Contact of Rough Surfaces. Tribol. Trans. 2003, 46, 383–390. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. A Static Friction Model for Elastic-Plastic Contacting Rough Surfaces. J. Tribol. 2004, 126, 34–40. [Google Scholar] [CrossRef]

- Sugimura, J.; Kimura, Y. Characterization of topographical changes during lubricated wear. Wear 1984, 98, 101–116. [Google Scholar] [CrossRef]

- Sugimura, J.; Kimura, Y.; Amino, K. Analysis of the topographical changes due to wear—Geometry of the running-in process. J. Jpn. Soc. Lubr. Eng. 1986, 31, 813–820. [Google Scholar]

- Kimura, Y.; Sugimura, J. Microgeometry of sliding surfaces and wear particles in lubricated contact. Wear 1984, 100, 33–45. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, H.; Kovalev, A.; Meng, Y. Numerical Running-In Method for Modifying Cylindrical Roller Profile Under Mixed Lubrication of Finite Line Contacts. J. Tribol. 2019, 141, 041401. [Google Scholar] [CrossRef]

- Evans, H.; Snidle, B. Analysis of micro-elastohydrodynamic lubrication for engineering contacts. Tribol. Int. 1996, 29, 659–667. [Google Scholar] [CrossRef]

- Johnson, K.; Greenwood, J.A.; Poon, S. A simple theory of asperity contact in elastohydro-dynamic lubrication. Wear 1972, 19, 91–108. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R. Elasto-Hydrodynamic Lubrication: The Fundamentals of Roller and Gear Lubrication; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Roelands, C.J.A.; Winer, W.O.; Wright, W.A. Correlational Aspects of the Viscosity-Temperature-Pressure Relationship of Lubricating Oils (Dr In dissertation at Technical University of Delft, 1966). J. Lubr. Technol. 1971, 93, 209–210. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Tripp, J.H. The Elastic Contact of Rough Spheres. J. Appl. Mech. 1967, 34, 153–159. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Tripp, J.H. The Contact of Two Nominally Flat Rough Surfaces. Proc. Inst. Mech. Eng. 1970, 185, 625–633. [Google Scholar] [CrossRef]

- Bush, A.; Gibson, R.; Thomas, T. The elastic contact of a rough surface. Wear 1975, 35, 87–111. [Google Scholar] [CrossRef]

- McCool, J.I. Comparison of models for the contact of rough surfaces. Wear 1986, 107, 37–60. [Google Scholar] [CrossRef]

- Halling, J.; Nuri, K. Elastic/plastic contact of surfaces considering ellipsoidal asperities of work-hardening multi-phase materials. Tribol. Int. 1991, 24, 311–319. [Google Scholar] [CrossRef]

- Zhao, Y.; Maietta, D.M.; Chang, L. An Asperity Microcontact Model Incorporating the Transition From Elastic Deformation to Fully Plastic Flow. J. Tribol. 2000, 122, 86. [Google Scholar] [CrossRef]

- Jamari, J.; Schipper, D.J. An elastic–plastic contact model of ellipsoid bodies. Tribol. Lett. 2006, 21, 262–271. [Google Scholar] [CrossRef]

- Jackson, R.L.; Green, I. A Finite Element Study of Elasto-Plastic Hemispherical Contact Against a Rigid Flat. J. Tribol. 2005, 127, 343–354. [Google Scholar] [CrossRef]

- Jackson, R.L.; Green, I. A statistical model of elasto-plastic asperity contact between rough surfaces. Tribol. Int. 2006, 39, 906–914. [Google Scholar] [CrossRef]

- Nayak, P.R. Random Process Model of Rough Surfaces. J. Lubr. Technol. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Bush, A.; Gibson, R.; Keogh, G. The limit of elastic deformation in the contact of rough surfaces. Mech. Res. Commun. 1976, 3, 169–174. [Google Scholar] [CrossRef]

- Beheshti, A.; Khonsari, M.M. Asperity micro-contact models as applied to the deformation of rough line contact. Tribol. Int. 2012, 52, 61–74. [Google Scholar] [CrossRef]

- Hartinger, M.; Dumont, M.-L.; Ioannides, S.; Gosman, D.; Spikes, H. CFD Modeling of a Thermal and Shear-Thinning Elastohydrodynamic Line Contact. J. Tribol. 2008, 130, 041503. [Google Scholar] [CrossRef]

- Hartinger, M.; Gosman, D.; Ioannides, S.; Spikes, H. Two-and Three-Dimensional CFD Modelling of Elastohydrodynamic Lubrication. In Proceedings of the 34th Leeds–Lyon Symposium on Tribology, Lyon, France, 4–7 September 2007. [Google Scholar]

- Reynolds, O. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. R. Soc. Lond. 1886, 177, 157–234. [Google Scholar] [CrossRef]

- Venner, C.H.; Lubrecht, A.A. Multilevel Methods in Lubrication; 1. Auflage; Elsevier: Amsterdam, The Netherlands, 2000; ISBN 0-444-50503-2. [Google Scholar]

- Habchi, W.; Demirci, I.; Eyheramendy, D.; Morales-Espejel, G.; Vergne, P. A finite element approach of thin film lubrication in circular EHD contacts. Tribol. Int. 2007, 40, 1466–1473. [Google Scholar] [CrossRef]

- Marian, M.; Weschta, M.; Tremmel, S.; Wartzack, S. Simulation of Microtextured Surfaces in Starved EHL Contacts Using Commercial FE Software. Mater. Perform. Charact. 2017, 6, 165–181. [Google Scholar] [CrossRef]

- Brooks, A.N.; Hughes, T.J. Streamline upwind/Petrov-Galerkin formulations for convection dominated flows with particular emphasis on the incompressible Navier-Stokes equations. Comput. Methods Appl. Mech. Eng. 1982, 32, 199–259. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L.; Nithiarasu, P. The Finite Element Method for Fluid Dynamics; 7. Aufl.; Elsevier Butterworth-Heinemann: Oxford, UK, 2014; ISBN 1306160901. [Google Scholar]

- Marian, M.; Grützmacher, P.G.; Rosenkranz, A.; Tremmel, S.; Mücklich, F.; Wartzack, S. Designing surface textures for EHL point-contacts—Transient 3D simulations, meta-modeling and experimental validation. Tribol. Int. 2019, 137, 152–163. [Google Scholar] [CrossRef]

- Kragelsky, I.V.; Alisin, V.V. Friction Wear Lubrication: Tribology Handbook; Elsevier Science & Technology, ProQuest: Kent, UK; Ann Arbor, MI, USA, 2016; ISBN 9781483165950. [Google Scholar]

- Fleischer, G.; Gröger, H.; Thum, H. Verschleiß und Zuverlässigkeit; Verl. Technik: Berlin, Germany, 1980. [Google Scholar]

- Archard, J.F.; Hirst, W. The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Holm, R. Electric Contacts: Theory and Application, Fourth Completely Rewritten ed.; Springer: Berlin/Heidelberg, Germany, 1967; ISBN 978-3-662-06688-1. [Google Scholar]

- Wriggers, P.; Laursen, T.A. Computational Contact Mechanics; Springer: Wien, Austria; New York, NY, USA, 2007; ISBN 978-3-540-32609-0. [Google Scholar]

- Bhushan, B. Modern Tribology Handbook; CRC Press: Boca Raton, FL, USA, 2001; ISBN 9780849384035. [Google Scholar]

- Czichos, H.; Habig, K.-H. Tribologie-Handbuchb. Tribometrie, Tribomaterialien, Tribotechnik; 4, vollst. überarb. u. erw. Aufl. 2015; Springer: Wiesbaden, Germany, 2015; ISBN 978-3-8348-2236-9. [Google Scholar]

- Habchi, W. Finite Element Modeling of Elastohydrodynamic Lubrication Problems; John Wiley & Sons Incorporated: Newark, NJ, USA, 2018; ISBN 978-1119225126. [Google Scholar]