Proper fitting and mounting are critical to the performance, longevity, and efficiency of bearings. Engineers need to consider several factors to ensure the bearings are installed correctly and can operate at their best.

Below, we highlight important aspects of fitting and mounting that can help improve bearing performance in various applications.

Below, we highlight important aspects of fitting and mounting that can help improve bearing performance in various applications.

Scroll down to learn how to maximize bearing life and performance.

“Bearings should be mounted with the goal of achieving proper fit without interference or looseness.”

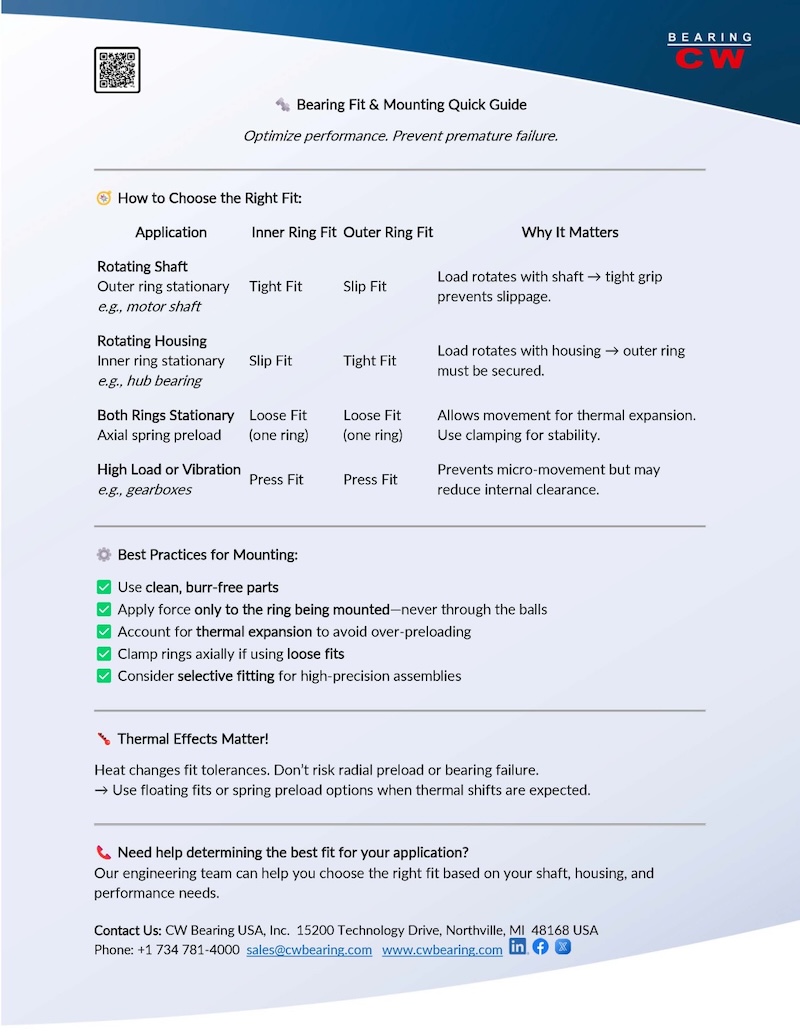

Fitting Tolerances and Mounting Guidance

Bearings should be mounted with the goal of achieving proper fit without interference or looseness.

However, several factors need to be accounted for:

- Ease of assembly/disassembly

- Precision of machining tolerances

- Operating conditions (load, speed, temperature)

- Axial thermal expansion

- Rigidity and rotational accuracy requirements

For specific applications, such as constant radial loads, point loads, or rotating components, choosing the right fit ensures efficient bearing operation and longevity.

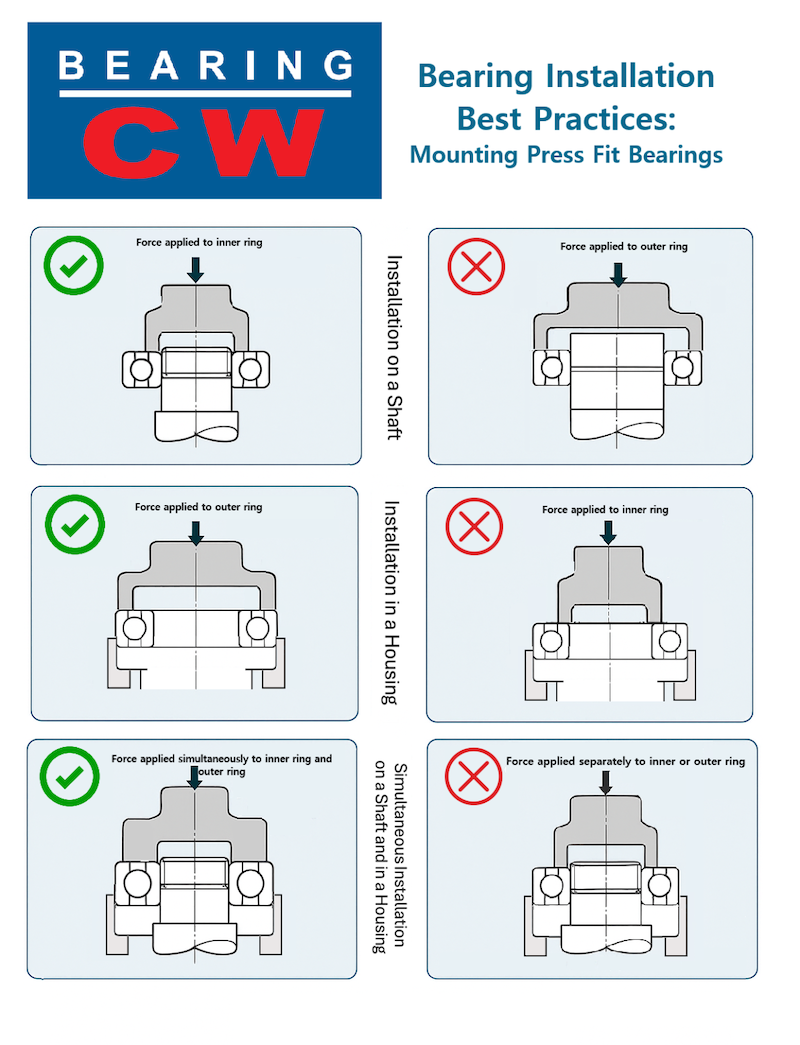

Key Mounting Considerations:

- Clean and Burr-Free Parts: For optimal alignment, it’s essential to assemble bearings only with clean, burr-free parts. Even small impurities on the shaft or housing can lead to misalignment, reducing bearing performance.

- Proper Force Application: When applying mounting force, it should be directed equally to the ring that needs press-fitting. Avoid applying force through the balls from one ring to the other, as this can cause damage during the assembly process.

- Consider Preload and Geometry: Tight press fits can reduce radial clearance. To prevent unnecessary preload, engineers should carefully consider shaft and housing geometry and the accuracy of the fit. Preloading springs should use one bearing with a loose fit to ensure proper spring loading.

- Axial Run-Out Minimization: If both rings have a loose fit, it is recommended to clamp the inner and outer rings together. This minimizes axial run-out and ensures smooth bearing operation.

- Temperature-Related Expansion: Mounting fits can be significantly affected by temperature changes, as different components expand at different rates. This can lead to radial preloading and even bearing failure. To prevent this, ensure one bearing is floating or has an axial loose fit to allow for thermal expansion.

The Right Fit for Every Bearing Application

Choosing the correct shaft and housing fit is critical to bearing life, efficiency, and reliability.

From slip fits for thermal expansion to press fits for high-load environments, proper mounting prevents micro-movement, reduces friction, and protects against premature failure.

Contact:

CW Bearing USA, Inc. 15200 Technology Drive,

Northville, MI 48168 USA

Email: sales@CWBearing.com