Whether in machine tools, printing presses, medical technology, or aerospace – wherever maximum precision and reliability are essential, high-precision bearings demonstrate their strengths. With their ability to operate at very high speeds, precisely absorb both axial and radial loads, and maintain consistent running accuracy, they play a decisive role in industrial productivity and quality.

A look back at their development shows how the requirements for this bearing type have continuously evolved – always driven by new technologies and market demands. At the same time, current R&D work provides a clear view of the future: from more efficient materials and smart sensor technology to more sustainable lubrication concepts.

Retrospective: From Speed Increases to Service Life and Cost Efficiency

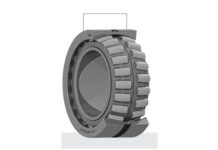

In the 1980s and 1990s, the primary focus was on higher speeds. To meet growing performance demands, hybrid bearings with ceramic rolling elements were introduced on a large scale. Silicon nitride balls are not only lighter and harder than steel, they also generate less friction, less heat, and lower centrifugal forces – a decisive advantage in high-speed spindles.

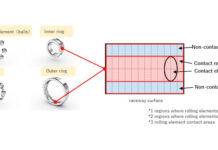

In parallel, bearing geometries were refined, for example by using smaller balls with the same bearing diameter, and by developing preload strategies. Different arrangements such as O, X, or tandem configurations opened up new possibilities to tailor stiffness and load capacity to specific applications.

From the 2000s onward, the focus shifted. Beyond speed and precision, service life, ease of maintenance, and cost efficiency gained importance. Grease lubrication became the dominant trend, offering easier handling, lower infrastructure requirements, and reduced environmental impact compared to oil-air lubrication. Manufacturers responded with innovative solutions such as sealed bearings with integrated grease reservoirs, which operate reliably for many years without relubrication.

Today: Efficiency, Flexibility, and Digital Support

Today’s requirements for high-precision bearings are more complex than ever. Machine tools are becoming more compact, while also more versatile and highly automated. Bearings must therefore deliver top performance in confined spaces while ensuring long-term reliability.

A key development in this context is the reduction of vibrations. Advanced cage designs and new materials, such as glass- or carbon-fiber reinforced PEEK, provide better lubricant flow, lower mass inertia, and higher stability. The result: improved surface quality of machined parts and extended bearing service life.

At the same time, digitalization has made its way into bearing technology. Simulation tools and calculation software help engineers select the right bearing configuration, determine stiffness and preload, and run through different scenarios quickly. This shortens development cycles and enables solutions that are precisely tailored to customer requirements.

Looking Ahead: Sustainability, Sensor Technology, and Smart Bearings

In the coming years, four overarching themes will shape the future of high-precision bearings: sustainability, digitalization with AI-driven processes, miniaturization, and new applications in electromobility.

- Sustainability and Energy Efficiency Demand is growing for bearings that require minimal lubrication while offering long service life. Self-lubricating systems or bearings with integrated grease reservoirs that operate without external energy supply will become increasingly important.

- Digitalization, Smart Bearings, and AI Sensors and connectivity are transforming bearing technology. Early systems already measure parameters such as temperature, vibration, or lubricant condition in real time. This enables predictive maintenance and helps reduce downtime. The next step is integrating smart bearings into IoT environments, feeding data directly into higher-level systems. Artificial intelligence will play a key role in analyzing this data, identifying patterns, and enabling even more precise process optimization – up to machines that autonomously adjust their operating parameters.

- Miniaturization and Micro Applications Industries such as medical technology and semiconductor manufacturing are driving demand for extremely small, high-precision bearings. Despite their tiny dimensions, they must withstand speeds of several hundred thousand revolutions per minute while maintaining maximum accuracy. New hybrid materials and ultra-light ceramics will be critical in this field.

- Electromobility and New Manufacturing Technologies The electrification of the automotive industry opens significant opportunities for high-precision bearings. In electric vehicles, they improve the efficiency and performance of electric motors, directly enhancing range, sustainability, and overall performance. At the same time, additive manufacturing and 3D printing are creating new possibilities for custom-designed high-precision bearings, offering tailor-made solutions for specific applications and greater flexibility for manufacturers.

High-precision bearings are a perfect example of how classic machine elements continually reinvent themselves through innovation. From speed and accuracy to sustainable lubrication concepts and smart sensor-based solutions – this technology is evolving in step with the demands of modern manufacturing.

For manufacturers, distributors, and end-users alike, one thing is clear: those who embrace these trends early can increase productivity and secure a competitive edge. The future belongs to energy-efficient, connected, and highly flexible bearings that are more than just components – they are key enablers of intelligent and sustainable production.

Looking for more technical insights? Check out the PICARD blog!

Source PICARD