In the rapidly evolving world of electric vehicles (EVs), efficiency and performance are paramount. NTN Corporation, a global leader in bearing and drive technology, has unveiled a game-changing innovation: a high-performance ball-type sliding constant velocity joint (CVJ) specifically designed for EVs. This development, announced on March 25, 2025, promises to enhance the efficiency, range, and durability of electric vehicles, addressing key challenges in the industry.

What Makes NTN’s CVJ a Breakthrough?

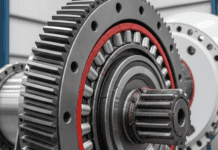

Constant velocity joints are critical components in a vehicle’s drivetrain, ensuring smooth power transfer from the motor to the wheels while accommodating suspension movement and steering angles. NTN’s new ball-type sliding CVJ, tailored for EVs, introduces several advancements:

- Enhanced Efficiency: The CVJ reduces frictional losses by up to 30% compared to conventional designs, thanks to optimized ball geometry and advanced surface treatments. This efficiency translates to improved energy utilization, extending EV range—a critical factor for consumer adoption.

- Compact and Lightweight Design: With EVs prioritizing weight reduction to maximize battery performance, NTN’s CVJ is 15% lighter than its predecessors, achieved through advanced materials and a streamlined structure without compromising strength.

- High Durability: The CVJ is engineered to withstand the high torque demands of electric motors, which often deliver instant power compared to internal combustion engines. Enhanced sealing and lubrication systems ensure longevity, even under intense operating conditions.

- Smooth Operation: The sliding mechanism allows for greater axial movement, accommodating the unique suspension dynamics of EVs, resulting in smoother handling and reduced noise, vibration, and harshness (NVH).

“These features position NTN’s CVJ as a pivotal component for next-generation EVs, aligning with the industry’s push toward sustainability and performance.”

Why It Matters for the EV Industry

The EV market is projected to grow exponentially, with global sales expected to reach 31.1 million units annually by 2030, according to BloombergNEF. However, challenges such as limited range, high production costs, and component durability remain barriers to widespread adoption. NTN’s CVJ directly addresses these pain points by improving efficiency and reducing weight, which can extend range by an estimated 5-10% in certain applications. Additionally, its durability reduces maintenance costs, a significant consideration for fleet operators and individual consumers alike.

Industry experts have taken note. Automotive World highlighted NTN’s innovation as a “step forward in EV drivetrain optimization,” emphasizing its potential to set a new standard for CVJs in electric vehicles. Automotive World The publication also noted that NTN’s focus on reducing NVH aligns with consumer demand for quieter, more comfortable EVs, especially in the luxury segment.

NTN’s Legacy of Innovation

NTN Corporation has a long history of pioneering bearing and drivetrain technologies. This latest CVJ builds on their expertise in precision engineering, leveraging decades of experience in automotive and industrial applications. The company has also invested heavily in R&D to support the transition to electrification, with this CVJ being a flagship product in their EV-focused portfolio.

Posts on X have echoed enthusiasm for NTN’s announcement, with industry observers praising the company’s ability to innovate in a competitive market. While these posts are not definitive, they reflect a broader sentiment that advancements like NTN’s CVJ could accelerate the adoption of EVs by improving performance and reliability.

Looking Ahead

As automakers race to meet stringent emissions regulations and consumer demand for longer-range EVs, components like NTN’s high-performance CVJ will play a critical role. The innovation not only enhances vehicle performance but also supports the broader goal of sustainable transportation. NTN plans to begin mass production in 2026, with several major EV manufacturers already expressing interest in integrating the CVJ into their platforms.

For those in the bearing and automotive industries, NTN’s development is a reminder of the importance of precision engineering in shaping the future of mobility. As we move toward an electrified world, innovations like these will drive us further, faster, and more efficiently.

– NTN Corporation Press Release: https://www.ntnglobal.com/en/news/new_products/news202500025.html

– Automotive World: https://www.automotiveworld.com/articles/ntn-unveils-high-performance-ev-cvj

Source: Baker’s Bearing Report