Concrete mixer trucks operate in an environment defined by heavy loads, fluctuating stresses, and severe contamination. At the centre of their drive system lies a two-stage planetary gearbox responsible for turning the drum throughout mixing, transport, and discharge. Because the drum sits at an incline and the concrete mass is constantly mixed, the gearbox must transmit a combination of radial, axial, and shock forces. These forces ultimately converge on the main spherical roller bearing, making it one of the most critical components in the gearbox assembly.

This bearing is required to perform reliably despite extremely low rotational speeds, high shock forces, high misalignment, and constant exposure to a contaminated working environment. It must accommodate substantial misalignment, up to ±6°, while enduring variable load conditions that evolve continuously throughout every mixing cycle.

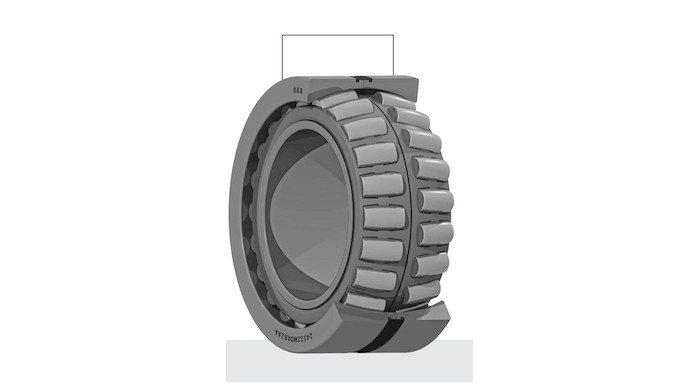

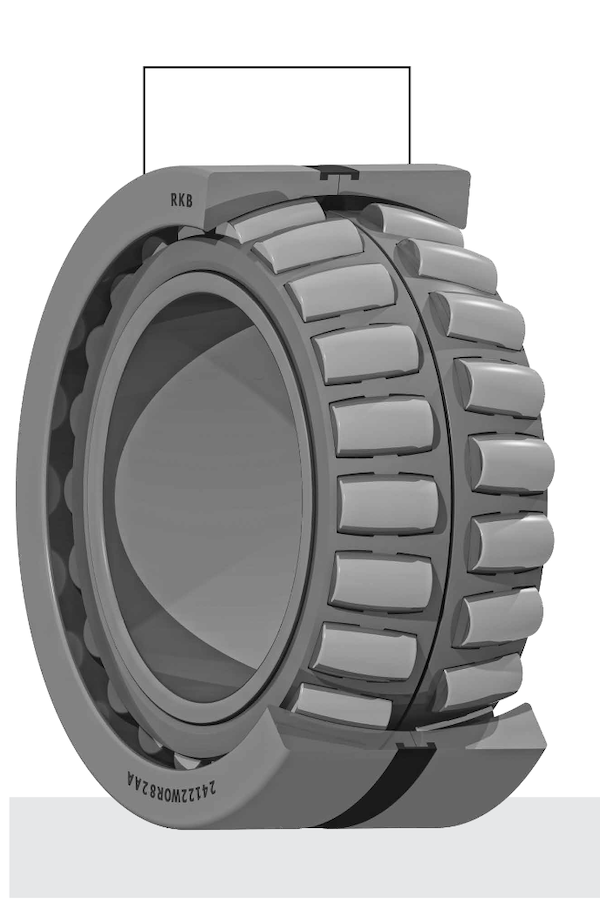

To address these demands, RKB developed a wide outer ring (WOR) spherical roller bearing specifically for concrete mixer drum drives. Three design variants were evaluated during development: the 24122 WOR82A, the 24122 WOR82, and the 24122 WOR82AA. Each incorporated different combinations of internal geometry, contact angles, cage architecture, roller symmetry, and rib design. The objective was to determine which configuration would provide the most favourable balance of misalignment capacity, internal load distribution, rolling contact behaviour, and fatigue-resistant service life.

Lubrication plays a particularly decisive role due to the drum’s low operating speed and inherent problems of suitable lubricant fluid film formation. RKB therefore assessed operating life using its ISO 281:2007–based rating software, which considers the full loading cycle, working temperature, lubricant viscosity at 40°C and 100°C, and the degree of environmental contamination. These analyses established that, when lubricated correctly, the WOR82AA configuration achieves and surpasses the service life required for this application.

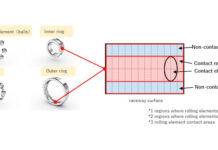

To validate mechanical behaviour, RKB conducted extensive FEM simulations using Ansys as well as NON-HERTZ semi-analytical calculations. These studies examined the reaction forces acting on each roller, the distribution of contact pressure across the bearing, and the resulting Von Mises stress patterns in the rings, rollers, and rib. Special attention was paid to the effect of misalignment, which significantly alters contact geometry and can produce localised stress concentrations. and optimised load distribution ultimately translate into increased reliability and significantly extended service life for the gearbox assembly. RKB RKB Bearing Industries Group is a Swiss-based manufacturing organization with decades of experience. RKB possesses the specialized knowledge and expertise to design and produce premium industrial bearings ranging from a 1 mm bore diameter to over a 2,000 mm outer diameter. With a global distribution footprint reaching over 70 countries, RKB provides value-driven solutions characterized by impressive operational adaptability, top-tier services, huge stock reserves, quick shipping times, and the hallmark quality expected of a premium bearing provider.

Among the three investigated designs, the WOR82AA consistently demonstrated the most favourable mechanical response. Its reinforced rib, symmetrical rollers, and increased number of rolling elements delivered lower internal stresses and reduced peak contact pressures. The pressure field across the bearing was more uniform, and roller guidance remained stable even under large misalignment angles. The combination of these features resulted in higher basic load ratings and improved fatigue life compared with the alternative designs.

Based on the combined results of the operating-life analysis, FEM simulations, and semi-analytical studies, the 24122 WOR82AA stands out as RKB’s most robust and efficient bearing solution for concrete mixer drum drives. Its ability to manage large misalignments, maintain low stress levels within the inner ring and rib, and operate reliably under low-speed lubrication and shock-loaded conditions makes it a highly durable option. The bearing’s improved internal geometry and optimised load distribution ultimately translate into increased reliability and significantly extended service life for the gearbox assembly.

RKB

RKB Bearing Industries Group is a Swiss-based manufacturing organization with decades of experience. RKB possesses the specialized knowledge and expertise to design and produce premium industrial bearings ranging from a 1 mm bore diameter to over a 2,000 mm outer diameter.

With a global distribution footprint reaching over 70 countries, RKB provides value-driven solutions characterized by impressive operational adaptability, top-tier services, huge stock reserves, quick shipping times, and the hallmark quality expected of a premium bearing provider.

This article is published in Motion+Drives December 2025 issue on pages 39-40