Tag: condition monitoring

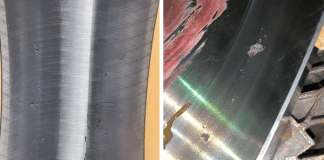

Bearing Failure Analysis as per ISO 15243 standard

https://youtu.be/G6j7Pfmm_G0?si=BMAQvJDKBv30bmP4

Reliability is the true currency of modern industry, and bearings play a central role in safeguarding it. During his presentation titled “Bearing Failure Analysis...

Why “Hearing” the Future is the Only Way to Protect It

We have arrived at a moment in industrial history that future generations will look back on as the “Great Transition”,or, as we call it...

Advancing Condition Monitoring in Hazardous Zones – Interview

The Story of SKF’s Microlog dBX

In high-risk industrial environments, safety-certified equipment is essential for preventing fires, explosions, and operational disruptions. To address the needs...

Ultrasound-Guided Lubrication & Condition Monitoring in Action – Ultrasound as a...

In this insightful presentation held during the Bearing & Power Transmission Forum, Haris Trobradovic dives into the practical and strategic implementation of ultrasound-guided condition-based lubrication and ultrasound-driven condition...

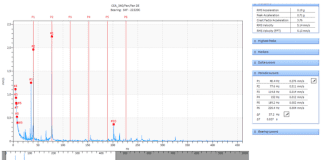

Early Bearing Fault Detection and Condition Monitoring in Baby Diaper Production...

In this project, early bearing fault detection will be performed on two motors in a baby diaper production line using the SDT340 ultrasound device.

The goal...

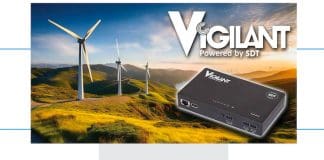

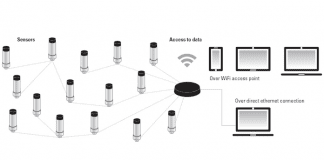

The Remote Condition Monitoring Solution with Ultrasound and Vibration Analysis

Vigilant: Enhancing Wind Turbine Efficiency

Wind turbines are pivotal to renewable energy production, yet maintaining their complex systems presents unique challenges. The Vigilant is a...

NKE FERSA and Nanoprecise Revolutionize Wind Turbine Maintenance with their New...

This strategic partnership introduces an AI-based condition monitoring solution that promises to transform wind farm operations worldwide.

In order to redefine wind turbine maintenance,...

The role of ultrasound in Maintenance 4.0 – Enabling Bearing Predictive...

Industry 4.0, the ongoing digital transformation of manufacturing, emphasizes intelligent machines, data-driven decision-making, and interconnected operations. Maintenance 4.0 will be a fundamental part of...

Timken Introduces New Wireless Sensor and Condition Monitoring Solution

The Timken Company, a global leader in engineered bearings and industrial motion products, has launched a new wireless sensor and condition monitoring solution to...

Schaeffler’s OPTIME Helps Prevent Unplanned Downtime at UK Limestone Plant

OPTIME wireless condition monitoring sensors are installed at the Tarmac Tunstead limestone plant to continuously monitor critical machines and auxiliary units.

A total...