Tag: maintenance

Bearing Failure Analysis as per ISO 15243 standard

https://youtu.be/G6j7Pfmm_G0?si=BMAQvJDKBv30bmP4

Reliability is the true currency of modern industry, and bearings play a central role in safeguarding it. During his presentation titled “Bearing Failure Analysis...

simalube service: improved maintenance efficiency and maximum equipment uptime

How a barely noticeable noise can change everything – and how the new 360° simalube service makes daily work easier for maintenance and production...

The Real Cost of Poor Lubrication — and How to Fix...

Most people in maintenance understand that poor lubrication causes failures. But what’s often underestimated is just how expensive those failures are, not only in...

What If Traditional Maintenance Didn’t Go Hand in Hand with Improved...

Electric and combustion motors are the heartbeat of industrial operations. From compressors and conveyors to pumps and fans, they power the processes that keep...

Smarter Maintenance of Industrial Assets

How I-care and MVP One are Transforming Industrial Reliability

In an industry where every hour of downtime costs millions, industrial manufacturers are under growing pressure...

What if Traditional Maintenance Didn’t Go Hand in Hand with Improved...

Electric and combustion motors are the heartbeat of industrial operations. From compressors and conveyors to pumps and fans, they power the processes that keep...

Avoiding Common Lubrication Mistakes for Bearing Optimisation

Getting the balance right between bearings and correct lubrication can be a challenge but is essential to maximising bearing health and longevity. Here Andrew...

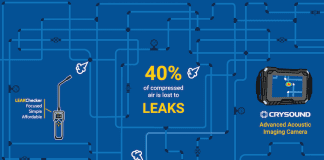

Energy, Safety, and Performance: The Tangible ROI of the Level 1...

When most companies hear the word “training,” they think of cost: time off the floor, travel expenses, registration fees. But what if training wasn’t...

A World First in Maintenance: Pump Grease with the Cordless Screwdriver

In the construction, agricultural and industrial sectors, unplanned machine breakdowns due to neglected lubrication repeatedly lead to high costs. Lutz Pumpen has therefore developed...

Why Poor Lubrication Still Costs So Much – And What You...

In many industrial plants, lubrication is still handled the same way it was decades ago: routine intervals, fixed quantities, generic greasing charts, and limited...