Tag: SDT

SDT Announces LUBExpert ON-GUARD

SDT Ultrasound Solutions is excited to announce the release of the LUBExpert ON-GUARD, the newest addition to the SDT Catalog, combining automation with reliability, simplicity,...

Ultrasound Measurement on Slewing Ring and Expertise After Replacement

For years, the reclaimer at a paper mill in north-western France had worked reliably, pivoting on three pinions mounted on reducers. The reclaimer is...

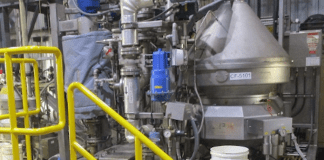

Critical Centrifuge Bearing Monitoring – Case Study

A centrifuge uses centrifugal forces, generated at high RPMs to separate solids and liquids. At Greenfield Ethanol, they use centrifuges in their manufacturing processes....

Mastering Ultrasound Monitoring with the CONMONSense Sensor Range: A Breakthrough in...

For industrial maintenance and condition monitoring practitioners, precision and reliability are paramount.

The SDT CONMONSense range of sensors is a game-changing solution, opening up a new...

Monitoring Extreme Slow Speed Wastewater Decanter with Ultrasound

10 Minute Acquisition Time – Monitoring an Extreme Slow Speed Wastewater Decanter with Ultrasound

This large wastewater decanter centrifuge is tasked with continuously separating solid...

Mechanical Condition Monitoring with the SDT340 & UAS3

https://youtu.be/8_J2LsTkDYE?si=H_i9IGA0afw1i7PN

Witness here the power of innovation as SDT delves into the world of precision maintenance. The SDT340 ultrasound detection device, combined with state-of-the-art analytics...

SDT Ultrasound Solutions presents the LUBExpert Implementation Master Class

Are you looking for a way to revolutionize your bearing lubrication practices and maximize equipment reliability? The LUBExpert Implementation Master Class is a comprehensive...

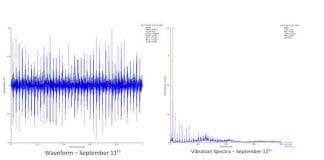

Greenfield Ethanol Failure Cause Analysis

Continuously Monitored using Vibration & Ultrasound Analysis

This BF-9401 Area Pulling Fan plays an integral role in Greenfield Ethanol’s manufacturing process. It is a critical...

Junior Reliability Technician Compares Experiences Using Vibration & Ultrasound

Trevor’s Introduction to Maintenance, Reliability, and Condition Monitoring

Back in late 2020, Trevor Bruinix began his career with SDT Ultrasound Solutions as a Junior Reliability...

Case Study: Diagnosing Bearing Failure w/ LUBExpert Static & Vibration Analysis

Torki works as a senior lubrication engineer at a cement manufacturer. He recently completed his Live Online Level One Ultrasound Certification with SDT Ultrasound...