Robust, high-performance stainless steel motion devices and protective accessories, coatings and greases ensure long, productive equipment lifetimes.

In food and beverage manufacturing, high volumes and continuous production pose significant challenges related to equipment maintenance and replacement. Not only do machines have high throughput demands, their critical components tend to wear out or fail frequently due to constant use in typically harsh, frequently sanitized environments. And with some machines and processes using thousands of bearings that can potentially fail, it doesn’t take much to bring a production line to an expensive and frustrating halt.

That’s why it pays to work with a motion component supplier that provides proven products and is well-positioned to both solve problems and get the right parts to you fast. This article will describe the elements to look for when selecting bearings and an ideal motion component specialist to ensure you obtain bearings that perform reliably and last a long time, so your food and beverage equipment will run as intended.

Common Food and Beverage Applications Require Reliable Bearings

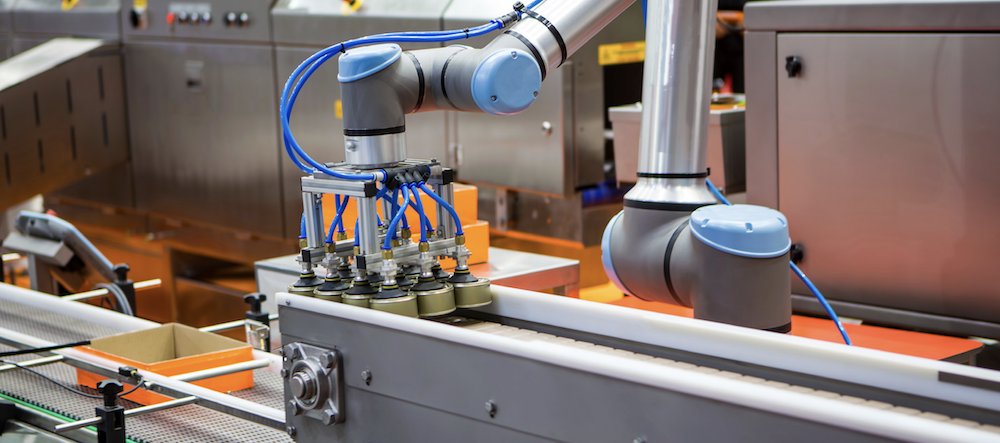

When your automated food or beverage machine requires controlled precise linear or smooth rotary motion, the bearings you choose must combine high performance and exceptional durability to optimize your production line’s throughput and efficiency. Here are some common automated food and beverage applications that particularly need a robust bearing outfitted for rust and contamination prevention and long life:

- Canning. Canning lines are one example of a food manufacturing process that uses thousands of bearings. In canning lines, bearings must reliably support higher speeds and reduce cycle times for maximum efficiency. Crossed roller bearings (CRBs) effectively handle heavy loads without vibrations that can otherwise damage the equipment.

- Packaging/filling/bottling. Efficient and accurate motion are critical in ensuring accurate fill labels and label placement in packaging and filling applications. Linear guides are often installed in mechanisms that move the products or containers horizontally or vertically into position with precision — such as underneath filling nozzles or onto labelling platforms. Rotary bearings are often found inside indexing mechanisms filling nozzles, capping applicators, or to rotate bottles for labelling.

- Conveyor Systems. Whether to process meat or move products through packaging and bottling processes, conveyor systems rely heavily on bearings. Linear guides align and help sort or position objects at various stages of transport. Crossed roller bearings are particularly effective in belt-driven conveyors capable of handling high loads or high volumes of goods.

- Meat processing. Linear guide rails help move various meats into place on conveyors or platforms, and they can guide cutting blades used to slice and dice meat products with precision.

- Mixers, tumblers and grinders. Rotary bearings are used in mixing arms and grinding blades for baked goods or meat products.

- Additive manufacturing. 3D printers aren’t just for plastics. Various machines can extrude or sinter ingredients into edible food creations like cakes, pastas and cultured meats. Linear bearings guide the print head or print bed to build layers and shapes for artistic or functional designs

Start With Stainless Steel

In food and beverage applications, the very agents that keep the environment clean cannot be tolerated for motion components. Large-scale operations may employ a clean-inplace (CIP) washdown method that involves water, detergents and sanitizers, while systems that need sterilization undergo steam-in-place (SIP) cleanings which use condensed steam as the cleaning medium. Each method is typically performed frequently and at high pressures, so it’s critical to choose a stainless steel material to resist moisture and avoid rust.

You can also find alternative corrosion-resistant materials for bearings in food and beverage manufacturing equipment, each having their own durability and hardness characteristics. However, they may not meet all of an application’s requirements and their costs may be prohibitive. In addition to stainless steel construction, specialized coatings and accessories can provide further protection against corrosion and contamination.

Keep Your Bearing Clean and Dry

While stainless steel materials are a good starting point for bearings, there are still areas of concern where a motion specialist can help bolster reliability and food safety. Working with the right motion company can mean the difference between high productivity and a frustrating stoppage when an integrated food processing line goes down. For example, IKO can collaborate with you to keep your bearings dry and rust-free while also preventing contaminants from potentially tainting food products. Here are just a few of our approaches:

- Food-grade grease. To protect against wear and corrosion for parts that may possibly make contact with food, look for an H-1 food-grade lubricant as classified by NSF (National Sanitation Federation) International.

- Armoloy Thin Dense Chrome. This surface treatment effectively protects metal parts against corrosion while improving surface hardness.

- Black chrome and fluorinated chrome. Black chrome forms a black permeable film on a surface to resist corrosion, followed by a protective acrylic resin coat. Fluorine black chrome also has these benefits and prevents foreign matter from adhering to the surface.

- Seals and end plates. An ideal motion specialist can offer specially engineered seals and plates for harsh or corrosive environments.

Look for a Wide Range of Durable Components Plus Engineering Expertise

As you begin evaluating motion components for your automated food application, there are many things to look for in a supplier. At IKO, for example, we offer a wide range of durable motion components in stainless steel versions, and a host of accessories and application support to ensure your part performs reliably and safely where messy food ingredients and high-pressure washdowns are prevalent. Our products lineup features linear guides in stainless steel versions and multiple sizes for superior corrosion resistance; CRBs with rollers alternately crossed at right angles to each other between inner and outer rings to handle loads from any direction at the same time, making them desirable for robotic end effectors that handle soft food items or in any other equipment with tight spaces; and bushings and cam followers with special design elements that are well-suited for use in food production equipment. Cam followers with IKO ThrustDisk™ technology, for example, feature a synthetic resin seal that prevents wear and contamination.

Online tools make it easy to identify and configure an ideal bearing. With an online configuration tool, you can add your design or application parameters to quickly customize a linear guide or rotary bearing. Also look for live online chat capabilities for immediate engineering assistance.

An ideal motion component specialist can also help you protect your investment and reduce maintenance needs. IKO linear guides and cam followers feature built-in C-Lube technology that uses capillary action to provide controlled release of lubricating oil to eliminate relubrication for five years or 12,500 miles without costly shutdowns and potential for contamination. C-Lube can be paired with an H-1 lubricant that prevents water or contaminants from getting into the bearing parts that may make incidental contact with foods. As previously mentioned, we can provide black chrome and fluorine black chrome surface treatments on the rail and slide units of linear bearings, as well as Armoloy TDC plating.

Custom Components Plus Local and National Support

In many cases, a standard product may not meet all your application needs. Remember to get in touch with your motion expert early and take advantage of their knowledge. Be sure to define the application and let them know about important factors such as whether you’re working on new or existing equipment, the end product it’s making, operating temperatures and even the geographical location of the facility, to name a few. With that information, IKO specialists can suggest the right combination of materials, greases, seals, coatings and other customizations you need for your part to perform in its intended food and beverage environment.

When you evaluate a supplier, focus on their ability to provide both local and national support. To minimize lead times, find a supplier with a large inventory of off-the-shelf products in multiple U.S. locations. This allows for faster delivery to a local facility should you need to quickly replace a critical part in your automated process. And, don’t overlook the rest of your operations. At IKO, we also understand that many food products are made throughout the U.S. That’s why when a customer comes to us to solve a problem, we team up with our distributor to document the solution across all of the customer’s facilities. This value added/value engineered (VAVE) philosophy helps plants resolve a problem promptly, should it arise, and avoid costly downtime at all locations.

Motion Components Engineered for Reliability in Food Applications

The productivity of your high-speed, high-volume food and beverage manufacturing processes depends on the reliability of your equipment. From frequent washdowns to contamination risks as well as several other harsh conditions in food production environments, motion components like linear guides and rotary bearings must be engineered for the job. With IKO’s combination of robust, high-performance motion devices made of stainless steel plus extensive protective accessories, coatings, C-Lube technology and food-grade lubricants, you have your food and beverage equipment’s recipe for optimal production and long life.

For more information, please visit the website at www.ikont.com.

Karl Wickenheisser,

VP of Sales & Marketing, IKO