How I-care and MVP One are Transforming Industrial Reliability

In an industry where every hour of downtime costs millions, industrial manufacturers are under growing pressure to move away from reactive fixes and towards proactive reliability. A new partnership between I-care, a global leader in predictive maintenance, and MVP One, a provider of advanced computerized maintenance management systems (CMMS), aims to change the rules of the game.

From Reactive Maintenance to Predictive Insight

From Reactive Maintenance to Predictive Insight

For decades, maintenance strategies have relied heavily on CMMS tools that track work orders and manage spare parts. But these systems often stop short of delivering the forward-looking insights manufacturers need. Predictive maintenance, powered by AI and IoT, can spot failures months in advance—yet too often, those insights remain trapped in data silos.

That’s where the I-care/MVP One integration comes in. By combining MVP One’s CMMS platform with I-care’s AI-driven predictive analytics, the two companies are building a complete reliability ecosystem. Instead of reacting to machine failures, reliability engineers can now plan interventions in advance, prioritize repairs based on severity, and schedule them during planned downtime.

“A Smarter Maintenance Capability”

“Manufacturers face a double threat: unplanned downtime from reactive maintenance, and the complexity of managing labor, parts, and compliance across facilities,” explains Ben Detober, Deputy CEO of I-care Group. “To overcome this disjointed environment, I-care and MVP One have created a smarter maintenance capability that uses predictive analytics to transform industrial asset management.”

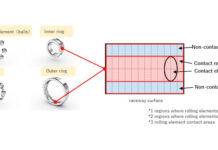

I-care brings decades of expertise in predictive maintenance, using vibration analysis, AI, and IoT sensors, while MVP One offers the structured backbone of a CMMS, ensuring that every maintenance task is tracked, prioritized, and executed efficiently. Together, they enable engineers to not only see problems before they occur but also act on them immediately within a single platform.

Reliability Without Surprises

The result is a system that puts reliability engineers back in control. “By combining MVP One’s CMMS with I-care’s AI-based predictive analytics, we have created a seamless reliability ecosystem, spanning work orders from waveforms,” says Jonathan Clark, CEO of MVP One. “Customers will be able to triage maintenance and repairs in real time, dramatically reducing the cost of unexpected production-stopping failures.”

This proactive approach doesn’t just save time and money, it extends the lifespan of industrial assets, ensures smoother operations, and ultimately gives manufacturers a competitive edge.

Part of a Larger Vision

For I-care, this partnership represents more than just a technical integration, it’s part of a larger ambition to become the single source of predictive maintenance data for reliability engineers worldwide. By embedding predictive insights directly into CMMS workflows, I-care is ensuring that vital data moves out of silos and into the hands of those who can use it to keep plants running at peak efficiency.

About MVP One

MVP One CMMS/EAM software is a market leader in turnkey maintenance management, empowering organizations with easy-to-use software that boosts asset lifespan. Connecting maintenance teams with innovative technology and expert guidance to work more efficiently, boosting their competitive edge. For more information, visit www.mvpone.com

About I-care

The I-care Group is a global leader in predictive maintenance, monitoring hundreds of thousands of industrial machines worldwide with advanced technologies—including our own Wi-careTM vibration sensors. Our mission is to change the way the world performs. I-seeTM, our AI-driven platform, integrates effortlessly with I-care solutions and external systems thanks to its open API. It gathers data from all PdM techniques, delivers equipment failure prediction months ahead, and feeds external systems with essential insights to optimize maintenance operations. Founded in 2004 in Belgium, I-care employs more than 950 people, operates 36 offices across 16 countries (Asia-Pacific, EMEA, and USA), and delivers worldwide expertise in reliability and predictive maintenance to customers in more than 55 countries. I-care has won several awards for its innovations, including ADM’s 2024 Supplier Award for reliability services, the Factory Innovation Award at Hannover Messe, and the 2025 Solutions Award at The Reliability Conference. For more information on I-see, Wi-care and I-care’s reliability technologies, visit www.icareweb.com

More information can be found on I-care web portal.

This article is published in BearingNews September 2025 issue on pages 101-102