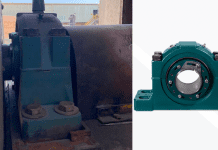

A crossed roller bearing, also called a crossed roller slideway, is effectively two sets of bearings and races combined at right angles to each other. Cylindrical bearings or rollers mount along the length of a rail in a carriage. The rollers crisscross each other and move between the two parallel guides (alternately termed table and bed) that surround the rollers. The rollers are between “V” grooved bearing ways or raceways ground out of the guides. The travel of the moving guide/table ends when it meets an end cap, a limiting component. The rollers are held in place with a cage, preventing roller-to-roller contact, which would increase friction and wear. Keeping rollers separated also eliminates any risk of them jamming.

Rollers provide a full line of contact rather than just the point of contact a ball bearing provides. This gives crossed roller bearings a broader contact surface and the ability to carry heavier loads. It also increases the bearing’s rigidity so it deforms less and is thus more accurate.

Because most crossed roller bearings do not have recirculating components, this source of vibration is eliminated. A benefit of not recirculating is less frictional resistance fluctuation, making them extremely quiet and smooth.

Visit NIPPON BEARING for more information.