BearingNews

BNL: 50 Years of Bearing Innovation

2020 is BNL’s 50th anniversary! In 1970 we introduced the BNL moulded plastic bearing to the market. Over five decades, our products have developed...

Lubrication of rolling bearings – How a timely application analysis can...

To ensure the reliable operation of rolling bearings, correct lubrication is a vital, and in practice all too often overlooked, factor. The main purpose...

NSK’s offering to the Food & Beverage industry

The food and beverage industry can be challenging when it comes to component selection. From extreme temperatures to high levels of contamination, machinery needs...

Bearings for Robotics

The bearings used in robotic applications must be high precision with good rotational accuracy and reliability. Articulated robotic arms, for example, require bearings in...

Mission Critical Success – Part 1

For unmanned vehicles that achieve hypersonic speeds, the performance of the combustion engine is paramount. Ball bearings play a pivotal role in the fuel...

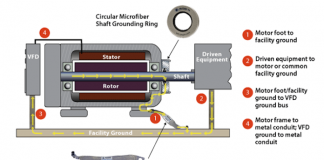

Electrical Bearing Protection Best Practices – Webinar on March 9th

A Webinar worth one Professional Development Hour/CPC Credit

Electro Static Technology (manufacturer of the AEGIS® Shaft Grounding Ring) has another training session coming up on best practices for...

Bearing Failure RCA: Pitting

When a rolling bearing is damaged during machine operation, the entire machine or equipment can seize or malfunction. Since bearings that fail prematurely or...

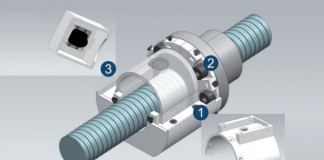

Camera-based Spindle Control Learning Model for Image-based Wear Quantification

Quantification of surface defects on ball screw drives is the prerequisite for timely exchange of the component in operation and the basis of knowledge...

Schaeffler is continuously expanding its range of service solutions

Three condition monitoring systems for different customer requirements and plant sizes

Schaeffler OPTIME: New addition brings CMS to the multitude of assets typically...

I-care Experts helping on a bearing failure detection with Wi-care 200...

I-care Predictive Maintenance department was called to help a chemical industry with a failure detection on its assets.

Wi-care 240 installation on the motor and...